Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry13 February 2017

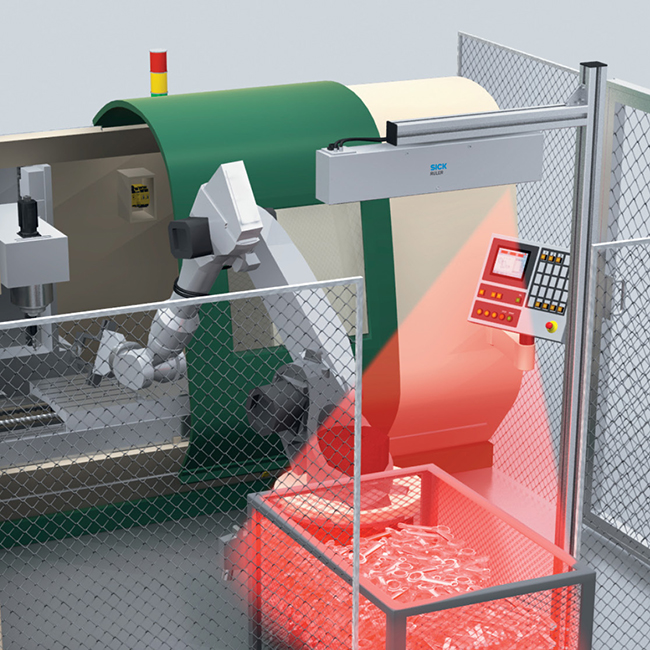

SICK automatic parts locating system with 3D vision - PLB

F.Fonseca presents automatic parts locating system with 3D vision - PLB from SICK

Automatic handling, especially when parts are transported in bulk, has great potential for process optimization and cost reduction. Automatic part selection and handling is not just a task, but a set of applications, depending on the specific process and part needs.

SICK'S PLB vision system is designed for precise location of randomly oriented parts in troughs and boxes. This system allows for easy introduction of new parts into the existing system in a short period of time thanks to CAD-based 3D localization software. The performance of SICK'S PLB vision system allows for high production rates.

The vision system consists of a 3D camera, tools and software for locating parts for easy integration and communication. The system's 3D camera ensures superior image quality and provides high immunity to ambient light. The widely-tested calibration tools and functions, communication with the robot and PLC make system integration into production quite simple. The hardware and software are integrated and pre-calibrated for the application.

The automatic locating system - 3D vision - SICK PLB has applicability in the detection of the position of parts for automatic handling in: smelting and forging and loading stations.

Automatic handling, especially when parts are transported in bulk, has great potential for process optimization and cost reduction. Automatic part selection and handling is not just a task, but a set of applications, depending on the specific process and part needs.

SICK'S PLB vision system is designed for precise location of randomly oriented parts in troughs and boxes. This system allows for easy introduction of new parts into the existing system in a short period of time thanks to CAD-based 3D localization software. The performance of SICK'S PLB vision system allows for high production rates.

The vision system consists of a 3D camera, tools and software for locating parts for easy integration and communication. The system's 3D camera ensures superior image quality and provides high immunity to ambient light. The widely-tested calibration tools and functions, communication with the robot and PLC make system integration into production quite simple. The hardware and software are integrated and pre-calibrated for the application.

The automatic locating system - 3D vision - SICK PLB has applicability in the detection of the position of parts for automatic handling in: smelting and forging and loading stations.

- 0

- 1