This Tuesday Carnival, 21/02, we’re closed! 🎭

Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

3D LiDAR sensors multiScan100 - SICK

The multiScan100 3D LiDAR sensor from SICK is a real multi-talent. Thanks to its high-resolution 0° scan layer, it is suitable for mapping and localization.

The sensor generates a 3D point cloud that can be used to detect people and objects. It effortlessly detects fall edges and overhanging obstacles. This is how it reliably protects mobile platforms from accidents and failures. Thanks to its large working range, the sensor is also suitable for stationary applications.

The sensor generates a 3D point cloud that can be used to detect people and objects. It effortlessly detects fall edges and overhanging obstacles. This is how it reliably protects mobile platforms from accidents and failures. Thanks to its large working range, the sensor is also suitable for stationary applications.

Barcode Readers 2D Image-based - SICK

Image-based code readers provide flexibility, high performance, convenience and simplicity.

Even at fast conveyor speeds, SICK image code readers can reliably detect and evaluate 1D, 2D, DPM (Direct Part Marking), and partially damaged codes. These readers identify markings on nearly any surface, including metal, glass, plastic or paper. Plus, different models, interfaces, and networking capabilities provide enormous application flexibility.

Even at fast conveyor speeds, SICK image code readers can reliably detect and evaluate 1D, 2D, DPM (Direct Part Marking), and partially damaged codes. These readers identify markings on nearly any surface, including metal, glass, plastic or paper. Plus, different models, interfaces, and networking capabilities provide enormous application flexibility.

Barcode scanners - SICK

SICK barcode scanners accelerate logistics and automation. Their excellent reading performance assures an optimum process flow even with poor quality or damaged barcodes.

The high scanning frequency enables a high process velocity. The integrated CAN network, with ease of use and implementation, benefits the connection to other controllers and other scanners. The compact connection modules are optional and save space and installation costs. The SICK range of barcode scanners provides the right solution for each task.

The high scanning frequency enables a high process velocity. The integrated CAN network, with ease of use and implementation, benefits the connection to other controllers and other scanners. The compact connection modules are optional and save space and installation costs. The SICK range of barcode scanners provides the right solution for each task.

Detection system AOS Prime - SICK

The versatile AOS Prime system has been developed with the aim of preventing costly collisions. It is used in a whole host of industries, including steel works, ports and railway industry sectors of various kinds. Two application packages have been developed in order to keep damage to a minimum and, as a result, reliably enhance the availability of the container loading equipment to a considerable degree: AOS104 RTG and AOS502 STS.

Driver assistance systems Backup Assistance System - SICK

The Backup Assistance System (BAS) from SICK minimizes the risk of collisions for manned forklift trucks. It monitors areas of the vehicle which are obstructed from view of the driver.

The BAS gives real-time feedback via visual and audible warnings when the forklift truck comes near a stationary or moving object. The compact system is based on a TiM3xx 2D LiDAR sensor that is engaged only when the forklift truck is in reverse, thereby eliminating false alarms when moving forward. The monitored area can be scaled up by adding an additional sensor.

The BAS gives real-time feedback via visual and audible warnings when the forklift truck comes near a stationary or moving object. The compact system is based on a TiM3xx 2D LiDAR sensor that is engaged only when the forklift truck is in reverse, thereby eliminating false alarms when moving forward. The monitored area can be scaled up by adding an additional sensor.

Flexible designed image-based code reader Lector61X - SICK

The small device for miniature codes and much more.

The Lector61X is the smallest image-based code reader of the Lector® series. It is used for the reliable detection of 1D, 2D and stacked codes and is characterized by excellent reading properties for very small codes, regardless of the surface quality or the material color. The compact housing with flexible cable routing makes it the ideal code reader for production lines where space is tight. Its variable and stepless focus adjustment enables use for long and short reading distances and low-cost installation is possible thanks to the snap-in mounting.

The Lector61X is the smallest image-based code reader of the Lector® series. It is used for the reliable detection of 1D, 2D and stacked codes and is characterized by excellent reading properties for very small codes, regardless of the surface quality or the material color. The compact housing with flexible cable routing makes it the ideal code reader for production lines where space is tight. Its variable and stepless focus adjustment enables use for long and short reading distances and low-cost installation is possible thanks to the snap-in mounting.

Flexible designed image-based code reader Lector63X – SICK

Lector63x is a new member of the image-based code reader family from SICK.

The Lector63x is a 2 MP reader developed in a compact but flexible design. The optical flexibility ensures optimal setups for your needs. It reads codes at various distances and speeds, small codes at high production speeds, long-range identification or reading over wide conveyor belts.

The Lector63x is a 2 MP reader developed in a compact but flexible design. The optical flexibility ensures optimal setups for your needs. It reads codes at various distances and speeds, small codes at high production speeds, long-range identification or reading over wide conveyor belts.

Identification systems RFID RFH5xx- SICK

The RFH5xx product family from SICK is the ideal solution for machines and systems in closed production and logistics processes in which objects have to be identified in tight spaces. The clearly defined detection ranges of these HF write/read devices enable reliable singulation of transponders, even at very small object distances.

Identification systems RFU65x - SICK

The measuring RFID device with integrated passage and direction detection.

The RFU65x RFID read/write device saves space, time, and costs when it comes to identifying vehicles and vehicle parts. This compact device is able to determine the angle from which the transponder responds. The RFU65x also features an integrated logic unit that processes data on the basis of algorithms. This makes it possible to deduce entry detection information plus a vehicle’s direction of movement when it drives through a receiving goods door, for example. Unlike other devices, the RFU65x does not require any additional external antennae. Not only does this cut down on costs, it also simplifies and accelerates application processes in logistics and the automotive industry.

The RFU65x RFID read/write device saves space, time, and costs when it comes to identifying vehicles and vehicle parts. This compact device is able to determine the angle from which the transponder responds. The RFU65x also features an integrated logic unit that processes data on the basis of algorithms. This makes it possible to deduce entry detection information plus a vehicle’s direction of movement when it drives through a receiving goods door, for example. Unlike other devices, the RFU65x does not require any additional external antennae. Not only does this cut down on costs, it also simplifies and accelerates application processes in logistics and the automotive industry.

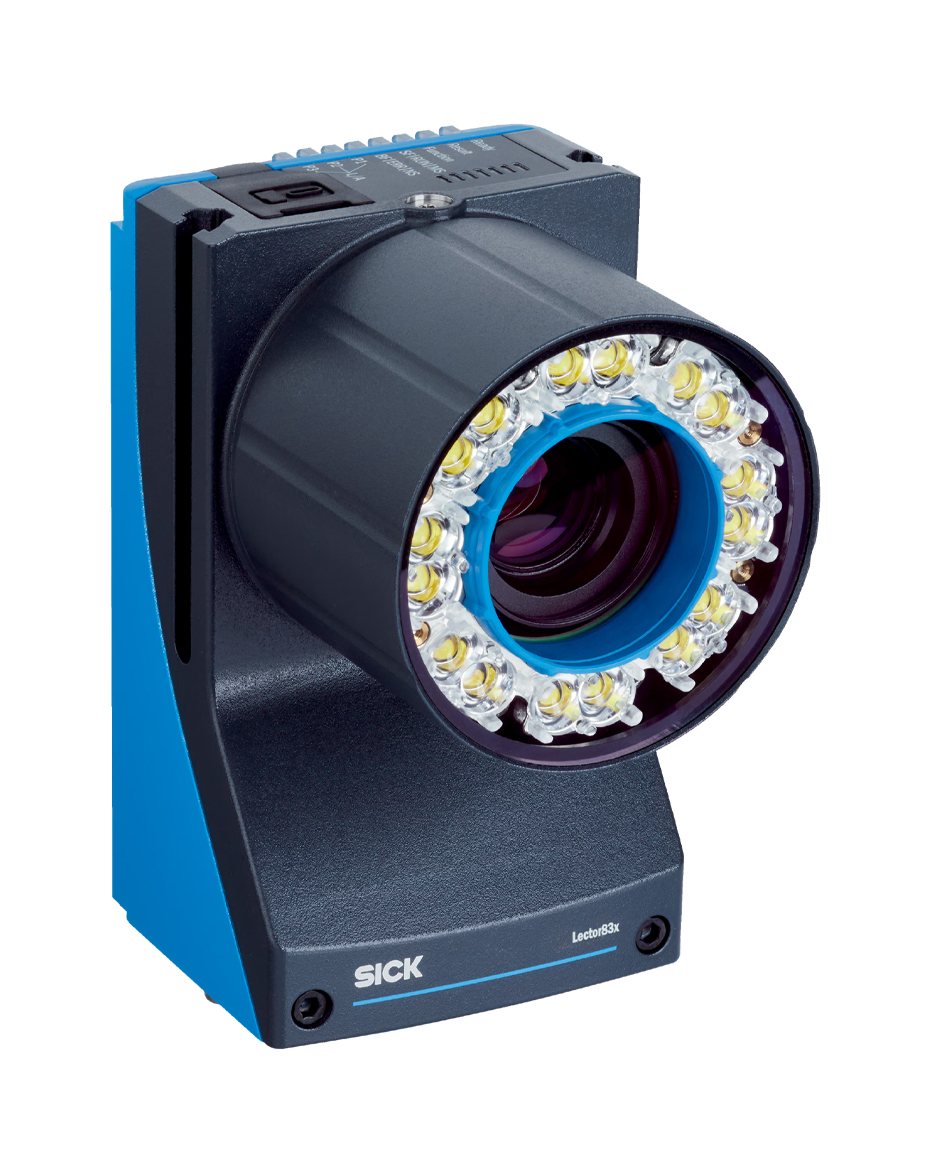

Image-based code reader Lector83x – SICK

The Lector83x image-based code reader from SICK offers high reading performance at medium reading distances and is easy to integrate into industrial networks. The compact camera has a resolution of 3 or 5 megapixels, a large depth-of-field control, and a wide field of view. In addition to high-performance multi-core processing, dual-port fieldbus, and multiple interfaces, the compact design reduces the number of required devices and installation effort at reading stations.

Using AI-based segmentation, the camera also identifies damaged codes at conveyor speeds of up to 2.5 m/s and correctly assigns them to objects. The Lector83x can be intuitively configured using a web server and is ready for use within a few minutes – even without specialist knowledge.

Using AI-based segmentation, the camera also identifies damaged codes at conveyor speeds of up to 2.5 m/s and correctly assigns them to objects. The Lector83x can be intuitively configured using a web server and is ready for use within a few minutes – even without specialist knowledge.

Image-based code readers Lector85x - SICK

The Lector85x image-based code from SICK reader is designed for very high scanning performance and equally high throughput. The small camera has a resolution of up to 12 megapixels, an enormous depth of field and field of view as well as very good computing power.

For reading stations, this means a compact design as well as fewer devices and installation work. When combined with AI-based segmentation, the camera reliably identifies codes even at conveyor speeds of up to 3.5 m/s and correctly assigns the codes to objects. This guarantees efficient identification processes and significantly reduces manual rework. The Lector85x can be intuitively configured using a web server and is ready for use within a few minutes – without the need for specialist knowledge.

For reading stations, this means a compact design as well as fewer devices and installation work. When combined with AI-based segmentation, the camera reliably identifies codes even at conveyor speeds of up to 3.5 m/s and correctly assigns the codes to objects. This guarantees efficient identification processes and significantly reduces manual rework. The Lector85x can be intuitively configured using a web server and is ready for use within a few minutes – without the need for specialist knowledge.

Laser scanner TiM5xx - SICK

More than simple object detection: The TiM5xx 2D laser scanner is a noncontact ranging solution within the TiM series from Sick. Thanks to its HDDM technology (High Definition Distance Measurement), the TiM5xx monitors large areas in indoor and outdoor applications

– regardless of the surface or ambient light. Enclosed in a compact, rugged housing, the TiM5xx provides accurate measurements of the scanned surface, making it possible to determine additional information such as the size and shape of objects. The TiM5xx can be used in variety of industrial applications as well as in building automation.

The integrated Ethernet interface makes easy implementation and remote maintenance possible. The TiM5xx is an efficient solution for stationary use as well as for use on automated guided vehicles (AGV) and other mobile applications.

– regardless of the surface or ambient light. Enclosed in a compact, rugged housing, the TiM5xx provides accurate measurements of the scanned surface, making it possible to determine additional information such as the size and shape of objects. The TiM5xx can be used in variety of industrial applications as well as in building automation.

The integrated Ethernet interface makes easy implementation and remote maintenance possible. The TiM5xx is an efficient solution for stationary use as well as for use on automated guided vehicles (AGV) and other mobile applications.

Laser scanners multi-layer MRS1000 - SICK

Outdoors is our fourth dimension.

With the MRS1000 multi-layer scanner, SICK has developed a 3D laser scanner which accurately and reliably detects and measures objects in good time and in multiple dimensions. By collecting large volumes of data on multiple scan layers and from different angles, it can detect and respond to objects on the floor as well as objects that are obstructing the path. The MRS1000 is characterized by a high degree of ruggedness even when subject to adverse environmental influences such as rain, dust, and fog. The new HDDM+ process, with multi-echo evaluation, ensures the reliable detection of objects and accurate measurement results. Versatile fields of application, both indoor and outdoor, make this an efficient all-rounder among 3D LiDAR sensors.

With the MRS1000 multi-layer scanner, SICK has developed a 3D laser scanner which accurately and reliably detects and measures objects in good time and in multiple dimensions. By collecting large volumes of data on multiple scan layers and from different angles, it can detect and respond to objects on the floor as well as objects that are obstructing the path. The MRS1000 is characterized by a high degree of ruggedness even when subject to adverse environmental influences such as rain, dust, and fog. The new HDDM+ process, with multi-echo evaluation, ensures the reliable detection of objects and accurate measurement results. Versatile fields of application, both indoor and outdoor, make this an efficient all-rounder among 3D LiDAR sensors.

Laser scanners multi-layer MRS6000 - SICK

Make the difference visible with multi layers.

The laser scanners multi-layer MRS6000 from SICK uses a high scanning point density and an aperture angle of 120° to reliably detect its environment across 24 layers. Special mirror technology ensures high scanning field stability. With the aid of multi-echo technology, the sensor scans through rain, dust and fog, while simultaneously multiplying the point density. These properties are particularly useful for creating a 3D point cloud without any gaps, which can be used to tackle a whole host of demanding applications.

The laser scanners multi-layer MRS6000 from SICK uses a high scanning point density and an aperture angle of 120° to reliably detect its environment across 24 layers. Special mirror technology ensures high scanning field stability. With the aid of multi-echo technology, the sensor scans through rain, dust and fog, while simultaneously multiplying the point density. These properties are particularly useful for creating a 3D point cloud without any gaps, which can be used to tackle a whole host of demanding applications.

Laser Scanners TiM1xx - SICK

Sensor for area monitoring: small, simple, cost-effective

Whether your application involves picking up the presence of an object in a specific area (detection) or determining its exact position (ranging), the LiDAR sensors in the TiM series are a highly efficient solution for both tasks.

Laser scanner TiM1xx from SICK is a small, simple, cost-effective laser scanner for a wide variety of area-monitoring applications. It is the starter model of the 2D LiDAR sensors from SICK and opens up new application possibilities with its compact design.

Whether your application involves picking up the presence of an object in a specific area (detection) or determining its exact position (ranging), the LiDAR sensors in the TiM series are a highly efficient solution for both tasks.

Laser scanner TiM1xx from SICK is a small, simple, cost-effective laser scanner for a wide variety of area-monitoring applications. It is the starter model of the 2D LiDAR sensors from SICK and opens up new application possibilities with its compact design.

Laser Scanners – SICK

The measuring laser scanners have a special position in the SICK product portfolio. Based on the Time of Flight (TOF) technology, these scanners are able to measure distances and profiles of the target objects.

Using the TOF scanners, SICK provides solutions throughout the world. Even the most demanding applications are being served: anti-collision for large harbor cranes, automatic plane parking, vehicle classification in free-flow traffic, guidance and protection of autonomous vehicles, anti-intrusion in building security, people counting in crowded public areas.

Using the TOF scanners, SICK provides solutions throughout the world. Even the most demanding applications are being served: anti-collision for large harbor cranes, automatic plane parking, vehicle classification in free-flow traffic, guidance and protection of autonomous vehicles, anti-intrusion in building security, people counting in crowded public areas.

LiDAR sensor picoScan100 - SICK

With a large scanning range, fine angular resolution and high sensitivity, the picoScan100 2D LiDAR sensor from SICK, successor of the TiM series, is setting new standards. It also reliably detects small and dark objects.

The sensor delivers exact measurement data and features integrated processing of data that is transmitted through various communication interfaces. The compact picoScan100 equipped with multi-echo technology has a rugged housing and ensures reliable measurement results even under harsh ambient conditions. It can be used in demanding industrial applications both in- and outdoors. The picoScan100 from SICK, available in three variants (Core, Prime and Pro), can also be adapted with other features to meet individualized requirements.

The sensor delivers exact measurement data and features integrated processing of data that is transmitted through various communication interfaces. The compact picoScan100 equipped with multi-echo technology has a rugged housing and ensures reliable measurement results even under harsh ambient conditions. It can be used in demanding industrial applications both in- and outdoors. The picoScan100 from SICK, available in three variants (Core, Prime and Pro), can also be adapted with other features to meet individualized requirements.

Localization systems Coriva – SICK

The Coriva System from SICK is a real-time localization system (RTLS) for industrial applications based on ultra-wideband. It determines the exact position of assets such as vehicles, workpieces, materials, etc. in real time. The recorded position data is used for seamless tracking and tracing of assets, thereby enabling continuous monitoring of goods movements and material flows. The system consists of mobile UWB tags (CorivaTag) , and a permanently installed infrastructure (CorivaSat) in the location area. The software (CorivaEngine) calculates the positions of the mobile devices. The recorded position data can be forwarded to an omlox hub via standardized interfaces. The Coriva System is omlox-certified and thus supports the world's first open standard for industrial localization systems.

Measurement & Identification systems DWS - SICK

DWS – Dimensioning, weighing and barcode reading from SICK

No matter if you handle small, large, heavy or lightweight packages, SICK has a solution. The combination of weight and volume defines the freight costs of packages.

Dimensioning weighing scanning (DWS) systems from SICK automatically measure weight and volume of packages and identify them by reading 1D or 2D codes. They can be integrated in existing conveyor systems and work reliably at conveyor speeds up to 2.9 m/s. SICK’s DWS systems are complete Legal-for-Trade solutions with integrated Alibi storage, meeting the requirements of the OIML R129 and R51-1 regulations as well as the Measuring Instruments Directive 2004/22/EG (MID).

No matter if you handle small, large, heavy or lightweight packages, SICK has a solution. The combination of weight and volume defines the freight costs of packages.

Dimensioning weighing scanning (DWS) systems from SICK automatically measure weight and volume of packages and identify them by reading 1D or 2D codes. They can be integrated in existing conveyor systems and work reliably at conveyor speeds up to 2.9 m/s. SICK’s DWS systems are complete Legal-for-Trade solutions with integrated Alibi storage, meeting the requirements of the OIML R129 and R51-1 regulations as well as the Measuring Instruments Directive 2004/22/EG (MID).

Measurement & Identification systems DWS Pallet - SICK

Measuring and weighing pallets and other bulky freight items.

The DWS Pallet track and trace system is a reliable solution when shipping bulky freight items such as pallets. The system helps logistics service providers such as freight forwarders, air freight service providers, and airlines detect freight for which the declaration is too low.

The freight is carried to the DWS Pallet with a forklift or pallet truck. It is then placed onto platform scales. As soon as the barcode attached to the freight item is identified using hand-held scanners, the length, width, volume, and weight of the freight is determined. A webcam can also be installed in the DWS Pallet to take a photo of the freight. Next, the data is shown on the integrated display, stored in a database, and transferred via standardized interfaces. Available upon request: special versions for larger freight items or for dynamic measurement.

The DWS Pallet track and trace system is a reliable solution when shipping bulky freight items such as pallets. The system helps logistics service providers such as freight forwarders, air freight service providers, and airlines detect freight for which the declaration is too low.

The freight is carried to the DWS Pallet with a forklift or pallet truck. It is then placed onto platform scales. As soon as the barcode attached to the freight item is identified using hand-held scanners, the length, width, volume, and weight of the freight is determined. A webcam can also be installed in the DWS Pallet to take a photo of the freight. Next, the data is shown on the integrated display, stored in a database, and transferred via standardized interfaces. Available upon request: special versions for larger freight items or for dynamic measurement.

Measurement & Identification systems DWS Static - SICK

Measuring size and weight for all shapes.

For the complete data capture of volume, weight and bar code information of freight for the courier, express, postal and cargo industry as well as for retail and warehousing, SICK developed the new DWS Static dimensioning weighing scanning system. The DWS510 Static uses one headed VMS510 volume measurement system and DWS520 Static is it’s big brother, using the doubleheaded VMS520 volume measurement system. Therefore it can dimension also non-cuboidal objects legal for trade, which is unique on the market for static DWS systems.

By simply pushing the scan button of the hand-held scanner, the DWS Static measures dimensions and weight of the parcel lying on the integrated roller conveyor. This data can be used for invoicing freight charges or it can be used in ERP systems to create freight documents automatically.

The system consists of the well-known VMS520 volume measurement system, a robust static scale and a hand-held bar code scanner, which are all integrated into a rugged steel frame.

For the complete data capture of volume, weight and bar code information of freight for the courier, express, postal and cargo industry as well as for retail and warehousing, SICK developed the new DWS Static dimensioning weighing scanning system. The DWS510 Static uses one headed VMS510 volume measurement system and DWS520 Static is it’s big brother, using the doubleheaded VMS520 volume measurement system. Therefore it can dimension also non-cuboidal objects legal for trade, which is unique on the market for static DWS systems.

By simply pushing the scan button of the hand-held scanner, the DWS Static measures dimensions and weight of the parcel lying on the integrated roller conveyor. This data can be used for invoicing freight charges or it can be used in ERP systems to create freight documents automatically.

The system consists of the well-known VMS520 volume measurement system, a robust static scale and a hand-held bar code scanner, which are all integrated into a rugged steel frame.

Measurement and Identification: Laser Positioning Systems Nav 200 | 300 | 350 - SICK

The demands made on modern goods transportation and the optimum navigation of automated guided vehicles (AGVs) are rising. Commonly used conventional positioning systems, such as guide wire systems or magnetic track guidance, mainly operate within an unchanging layout of routes. The requirement for flexible systems is, however, clearly on the rise.

Modern positioning systems such as the NAV 200, or NAV 3x0 from SICK offer considerable advantages here. The system provides maximum flexibility as a result of its unrestricted determination of position, via reflectors outside the work area. Even vehicles taken off track temporarily can find their own way back to their fixed route independently.

Modern positioning systems such as the NAV 200, or NAV 3x0 from SICK offer considerable advantages here. The system provides maximum flexibility as a result of its unrestricted determination of position, via reflectors outside the work area. Even vehicles taken off track temporarily can find their own way back to their fixed route independently.

Mobile hand-held scanners ZS36x8 PM - SICK

Reliable DPM code identification for challenging industrial applications.

The ZS36x8 DPM mobile hand-held scanner very quickly detects any code, whether 1D, 2D or DPM code. Size of the code, surface, contrast or density play almost no role. The ZS36x8 DPM also masters demanding marks such as needle embossing, laser etching, inkjet, chemical etching, inkjet casting, impressions and thermal coatings. But the same mobile hand-held scanner can also capture bar codes on labels under virtually any condition – including labels that are damaged, dirty, printed in poor quality or shrink-wrapped. That means the ZS36x8 DPM can be used absolutely anywhere: you get a mobile hand-held scanner that you can use on the production line for comprehensive tracking of materials and in the warehouse from goods receiving to shipping.

The ZS36x8 DPM mobile hand-held scanner very quickly detects any code, whether 1D, 2D or DPM code. Size of the code, surface, contrast or density play almost no role. The ZS36x8 DPM also masters demanding marks such as needle embossing, laser etching, inkjet, chemical etching, inkjet casting, impressions and thermal coatings. But the same mobile hand-held scanner can also capture bar codes on labels under virtually any condition – including labels that are damaged, dirty, printed in poor quality or shrink-wrapped. That means the ZS36x8 DPM can be used absolutely anywhere: you get a mobile hand-held scanner that you can use on the production line for comprehensive tracking of materials and in the warehouse from goods receiving to shipping.

Portable barcode readers - SICK

Data has to be recorded quickly and flexibly in almost all industries. Today, no other product does this work better than barcode scanners.

Portable barcode readers from SICK perform first-class work because without automatic scanners everything would have to be read off and registered manually. This takes too long and is susceptible to errors. When hand-held scanners are used as an interface for fully developed auto-identification solutions, data is recorded in seconds and reading errors are as good as impossible. It makes life easier for employees, processes are accelerated and sources of error are eliminated – in all departments of your industry.

Portable barcode readers from SICK perform first-class work because without automatic scanners everything would have to be read off and registered manually. This takes too long and is susceptible to errors. When hand-held scanners are used as an interface for fully developed auto-identification solutions, data is recorded in seconds and reading errors are as good as impossible. It makes life easier for employees, processes are accelerated and sources of error are eliminated – in all departments of your industry.

- 0

- 1