This Tuesday Carnival, 21/02, we’re closed! 🎭

Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Industrial Automation

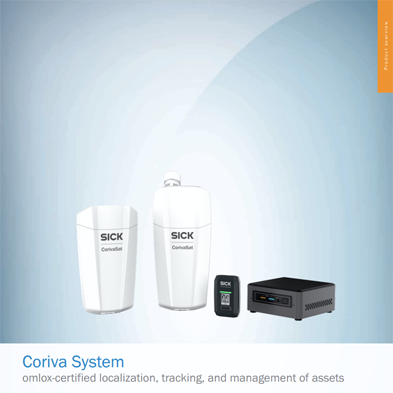

Localization systems Coriva – SICK

The Coriva System from SICK is a real-time localization system (RTLS) for industrial applications based on ultra-wideband. It determines the exact position of assets such as vehicles, workpieces, materials, etc. in real time. The recorded position data is used for seamless tracking and tracing of assets, thereby enabling continuous monitoring of goods movements and material flows. The system consists of mobile UWB tags (CorivaTag) , and a permanently installed infrastructure (CorivaSat) in the location area. The software (CorivaEngine) calculates the positions of the mobile devices. The recorded position data can be forwarded to an omlox hub via standardized interfaces. The Coriva System is omlox-certified and thus supports the world's first open standard for industrial localization systems.

more details

Downloads

Request Offer

Features

Advantages

Applications

F.Fonseca is the representative of SICK in Portugal.

- Flexible, scalable localization system for recording the position and condition data of assets;

- High positioning accuracy and precision thanks to UWB technology;

- Seamless integration into existing omlox infrastructures and interoperability with other Omlox-certified devices;

- Probabilistic localization thanks to advanced algorithms of the CorivaEngine;

- Provision of position data via standardized interfaces to one or more omlox hubs;

- Easy integration into existing IT and IoT infrastructures (K8s/K3s, Edge, Azure, AWS, OpenShift).

Advantages

- Seamless real-time overview of the location and movement of vehicles, workpieces, tools, and materials;

- Reduced search times, losses, and mix-ups thanks to clear identification and localization of assets;

- Automated and optimized processes, for example, through automated posting of material movements;

- High process transparency for audits and supervisory authorities;

- Certification according to the omlox standard ensures flexibility and compatibility.

Applications

- Automation of booking processes and completeness checks for picking processes;

- Efficient use of assets;

- End-to-end logistics with almost full transparency;

- Monitoring of goods movements and material flows in production and logistics;

- Tracking and tracing of assets.

F.Fonseca is the representative of SICK in Portugal.

Related products

- 0

- 1