Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Industrial Automation

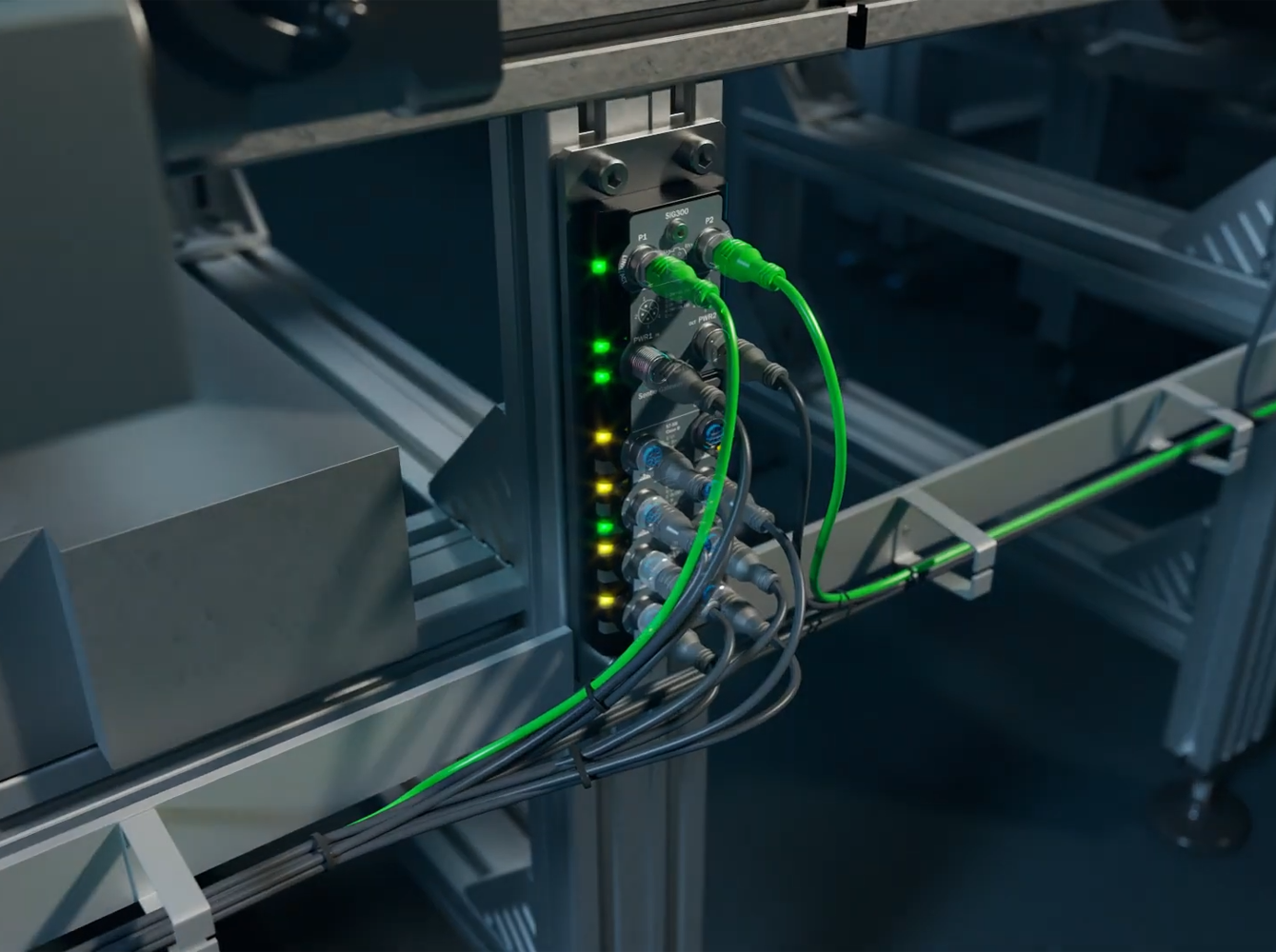

Sensor integration Gateway IO-Link SIG300 - SICK

The SIG300 Sensor integration gateway from SICK is a compact, high-performance IO-Link Master with eight ports (Class A/B) designed to collect, process, and transmit data from connected IO-Link devices to higher-level systems. With variants for PROFINET, EtherNet/IP, and EtherCAT as well as a REST API version, the SIG300 offers seamless integration into almost any industrial network. Its integrated web server and logic editor enable decentralized control, autonomous task execution, and simple configuration—directly via a browser. Providing up to 16 A total current supply (4 A per port), the SIG300 is ideal for demanding sensor and actuator applications in factory and logistics automation.

more details

Downloads

Request Offer

Features

Advantages

Applications

F.Fonseca is the representative of SICK in Portugal.

- 8 IO-Link ports (Class A/B): configurable as input or output;

- Ethernet interfaces: PROFINET, EtherNet/IP, EtherCAT;

- IIoT interfaces: REST API and MQTT;

- Galvanically isolated power supply pins (Class B);

- Integrated logic editor for autonomous functions;

- Web server for configuration and diagnostics;

- Protection rating: IP67;

- Power supply: 24 V DC ± 20 % / 16 A;

- Operating temperature: -20 °C to 70 °C;

- Housing material: Zinc die-cast, nickel-plated;

- Connection via M12 connectors (industrial standard).

Advantages

- Allows vertical integration in state-of-the-art production environments – from sensor through to the PLC system and to the cloud solution;

- High system compatibility through variants for the most commonly used Ethernet standards, as well as a REST API variant;

- High flexibility thanks to IO-Link ports that can also be configured as digital inputs or outputs;

- Fast response times due to remote data processing and process control via an integrated logic editor;

- Low cabling requirements thanks to the consolidation of several sensor signals into a single IO-Link message;

- Intuitive parameterization via an integrated web server.

Applications

- Areas in which sensors or actuators require class B ports;

- Creation of autonomous sensor systems in the logic editor without an additional controller;

- Integration of IO-Link sensor and actuator data into IIoT environments;

- IO-Link Master for factory and logistics automation.

F.Fonseca is the representative of SICK in Portugal.

- 0

- 1