Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Industrial Automation

Software SICK NOVA - SICK

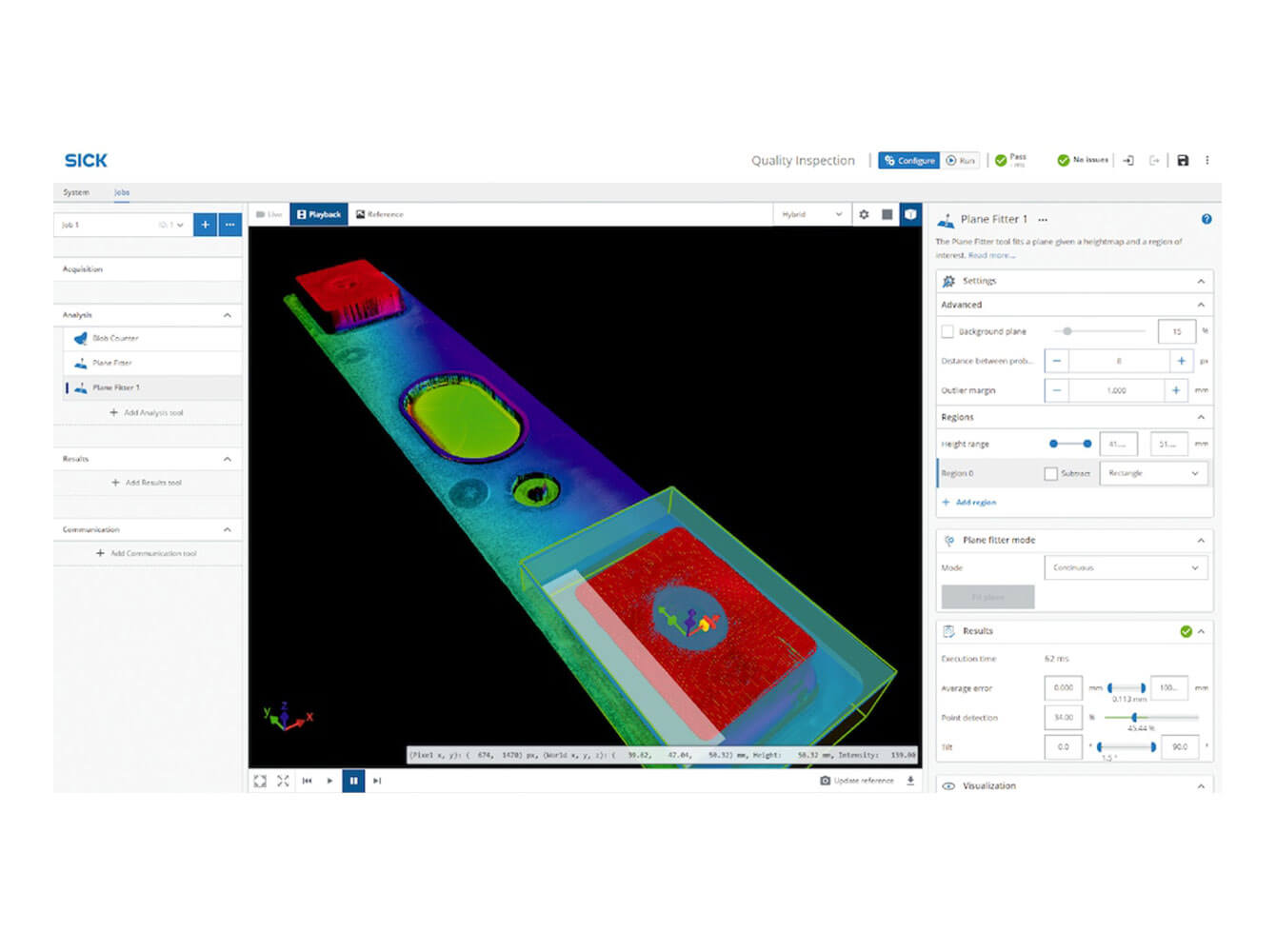

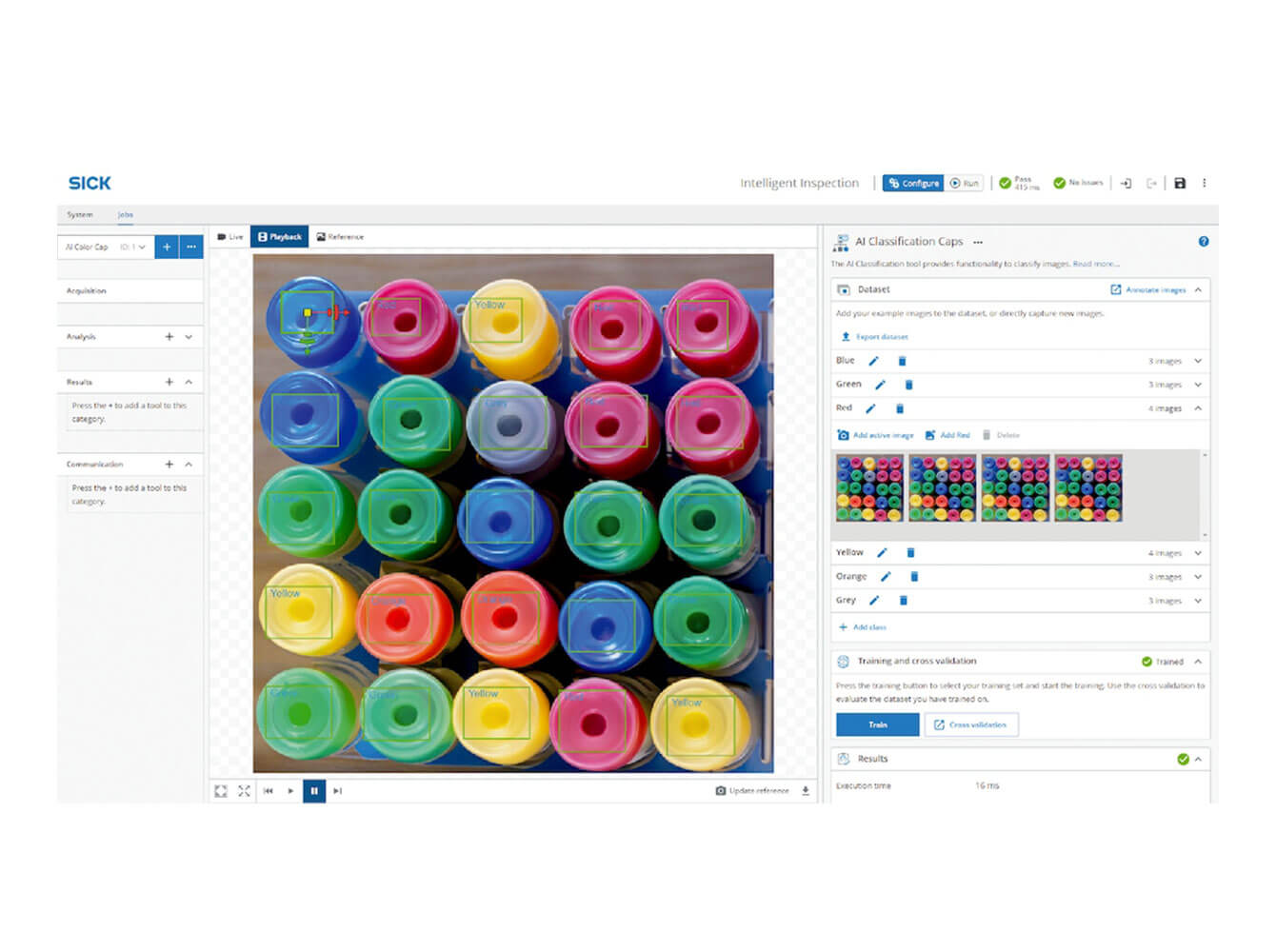

SICK Nova is the foundation software for configurable machine vision solutions in various industries and quality control applications.

Featuring a user-friendly web interface and AI capabilities, SICK Nova supports experts and non-experts alike so they can quickly and easily handle even the most challenging applications. SICK Nova runs on many 2D and 3D vision sensors and LiDAR sensors, leveraging different imaging technologies. Moreover, users can conveniently extend the software’s functionality with both user-developed and ready-made SICK Nova plug-ins. With this kind of scalability, SICK Nova is a safe choice that ensures cost-effective ownership.

Featuring a user-friendly web interface and AI capabilities, SICK Nova supports experts and non-experts alike so they can quickly and easily handle even the most challenging applications. SICK Nova runs on many 2D and 3D vision sensors and LiDAR sensors, leveraging different imaging technologies. Moreover, users can conveniently extend the software’s functionality with both user-developed and ready-made SICK Nova plug-ins. With this kind of scalability, SICK Nova is a safe choice that ensures cost-effective ownership.

more details

Request Offer

Features

Advantages

Industries

Applications

F.Fonseca is the representative of SICK in Portugal. sicknova-sim2500

- 2D and 3D machine vision inspection applications;

- Tools for presence, measuring, and quality inspection;

- AI capabilities for complex defect detection as well as classification tasks;

- Quick customization and addition of SICK Nova plug-in tools;

- Runs on a wide range of SICK vision sensors;

- Easy-to-use interface in web browser.

Advantages

- Automated quality analysis to improve production yield and speed – allow more fulfilling assignments for staff;

- Reliable inspections to reduce waste and avoid production downtime;

- Support for delivering high-quality products to ensure customer satisfaction;

- Advantages of using traditional rule-based tools in combination with on-device AI deep learning;

- Swift solution for special inspection needs through the use of plug-in tools;

- Capabilities for creating customized solutions;

- The supported SICK vision sensors fit various performance needs.

Industries

- Consumer goods;

- Logistics;

- Electronics;

- Machines and materials;

- Outdoor automation;

- Automotive.

Applications

- Completeness or empty checking;

- Complex and unpredictable defect detection;

- Complex classification and sorting;

- Detail inspection, counting, and measurement;

- Inline quality control;

- Manufacturing, assembly, and packaging verification;

- Part localization and measurement.

F.Fonseca is the representative of SICK in Portugal. sicknova-sim2500

- 0

- 1