Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Process, Instrumentation & Environment

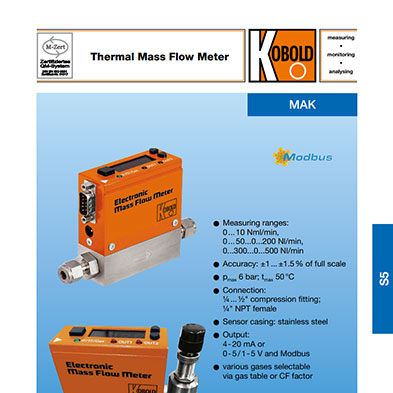

Thermal-mass flow meter MAK - Kobold

The thermal-mass flow meter MAK from Kobold has been specifically developed for accurate gas flow measurement where high precision, stability, robust construction, and versatility are essential.

The MAK measures the mass flow rate of gases directly, without the need for additional pressure or temperature compensation. The instrument uses a thermal measuring principle with two RTD elements mounted on the measuring tube: one is heated while the other senses the gas temperature. As the gas flows, it carries heat away from the heated sensor; the temperature difference between the two RTDs is proportional to the mass flow rate.

The MAK measures the mass flow rate of gases directly, without the need for additional pressure or temperature compensation. The instrument uses a thermal measuring principle with two RTD elements mounted on the measuring tube: one is heated while the other senses the gas temperature. As the gas flows, it carries heat away from the heated sensor; the temperature difference between the two RTDs is proportional to the mass flow rate.

more details

Downloads

Request Offer

The electronics convert this differential signal into a precise and stable output for display and transmission. In addition to the instantaneous flow rate, the MAK also provides integrated total flow indication.

A version with a precision needle valve integrated into the measuring system is available, enabling fine flow control and monitoring in compact form.

Features

Advantages

Applications

F.Fonseca is the representative of Kobold in Portugal.

A version with a precision needle valve integrated into the measuring system is available, enabling fine flow control and monitoring in compact form.

Features

- Measuring range: 0 – 10 Ncm³/min … 0 – 500 Nl/min (N₂);

- Accuracy: ±1.5 % of full scale;

- Repeatability: ±0.5 % of full scale;

- Process connection: ¼" NPT or ¼"–½" compression fitting;

- Material (wetted parts): Stainless steel;

- Maximum operating pressure: 6 bar;

- Maximum operating temperature: 50 °C;

- Power supply: 24 VDC;

- Outputs: Analogue (0–5 V, 1–5 V, or 4–20 mA), pulse output, Modbus;

- Display: Digital indicator with instantaneous and total flow indication;

- Signal lights: 2 LEDs for monitoring instantaneous and totalized flow values;

- Mounting position: Any orientation (horizontal recommended).

Advantages

- Direct mass flow measurement without the need for pressure or temperature compensation;

- Wide measuring range with high repeatability and stability;

- Negligible pressure loss due to bypass measuring system;

- Compact and lightweight construction for easy installation;

- Analog and pulse outputs, with optional Modbus interface;

- Two alarm outputs (configurable for any flow value);

- Integrated precision needle valve version for fine flow control;

- Immediate operation upon power connection (24 VDC);

- Suitable for various gases (selectable by configuration).

Applications

- Analysis devices

- Boiler controls

- Engineering

- Exhaust measurement

- Gas monitoring

- Laminator systems

- N₂/O₂-generators

- Paint lines

- Semiconductor industry

F.Fonseca is the representative of Kobold in Portugal.

Related products

- 0

- 1