Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Process, Instrumentation & Environment

variTRON 500 panel controller - JUMO

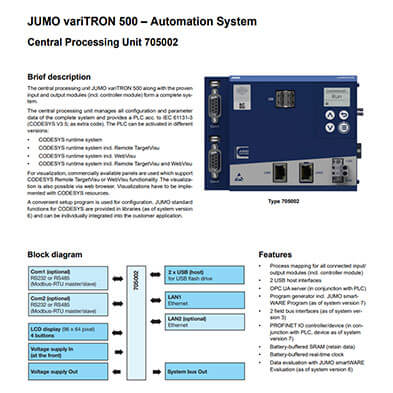

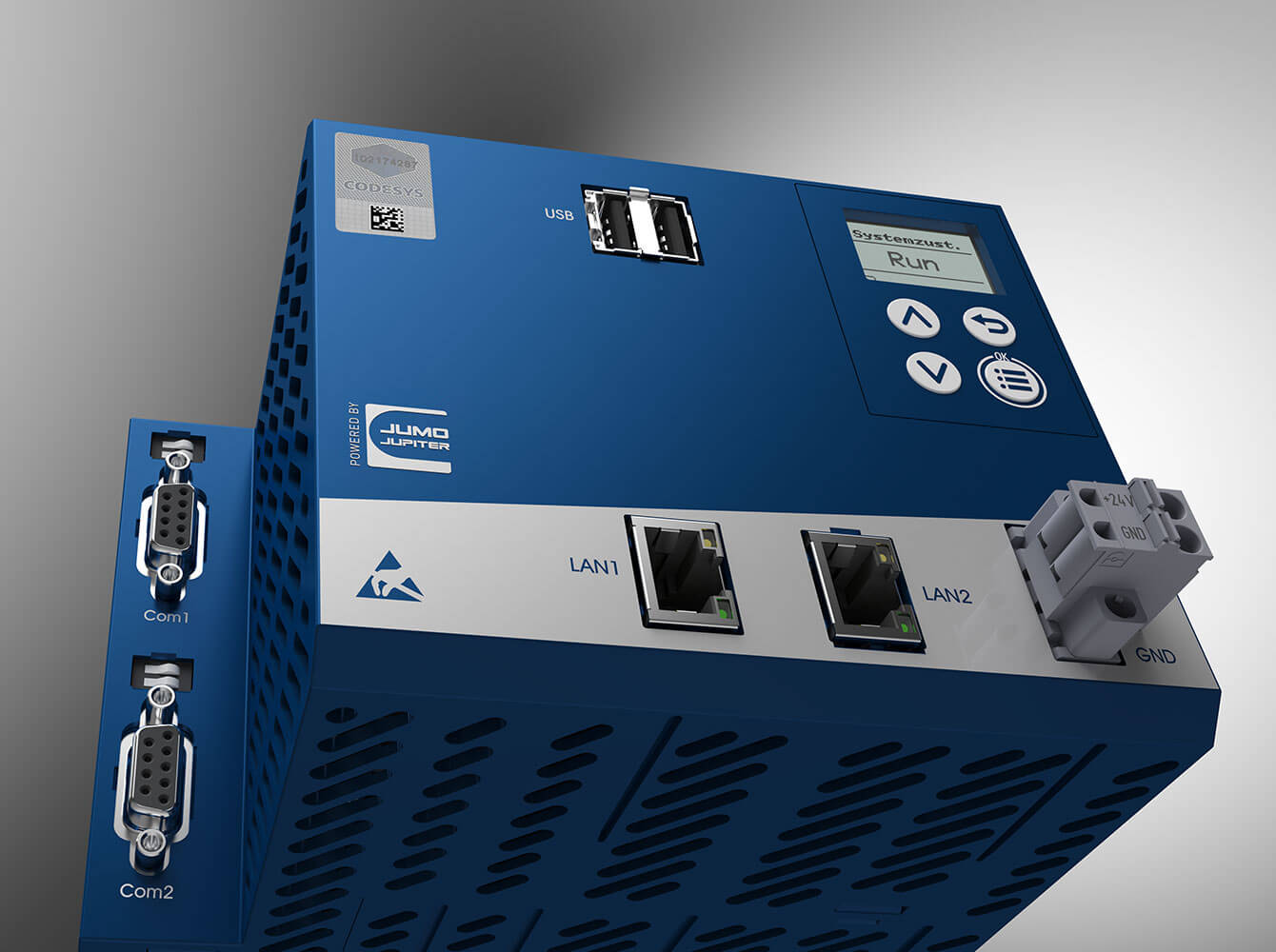

The variTRON 500 from Jumo is a central processing unit for automation systems and is architected upon the modular platform Jumo Jupiter. This central processing unit, in conjunction with the proven input and output modules (including the controller module) of the Jumo mTRON T measuring, control, and automation system, constitutes a comprehensive automation solution and provides a PLC functionality based on CODESYS V3.5.

The variTRON 500 incorporates a new hardware platform featuring an 800 MHz processor in a quad-core configuration, offering hardware and software scalability, resulting in a modular, flexible, and sustainable hardware platform integrated with a modern software architecture. Based on this new platform, innovative operating concepts can now be implemented using state-of-the-art display technologies.

The variTRON 500 incorporates a new hardware platform featuring an 800 MHz processor in a quad-core configuration, offering hardware and software scalability, resulting in a modular, flexible, and sustainable hardware platform integrated with a modern software architecture. Based on this new platform, innovative operating concepts can now be implemented using state-of-the-art display technologies.

more details

Downloads

Request Offer

Features

Advantages

Industries

F.Fonseca is the representative of Jumo in Portugal.

- Process mapping for all connected input/output modules (including controller module);

- 2x USB host interfaces;

- OPC UA server (in conjunction with PLC);

- Program generator including Jumo smartWARE Program (as of system version 7);

- 2x field bus interfaces (as of system version 3);

- PROFINET IO controller/device (in conjunction with PLC, device as of system version 7);

- Jumo Jupiter platform with 800 MHz quad-core processor;

- Jumo digiLine sensors for liquid analysis, thyristor power controller (via EtherCAT);

- More than 30 intelligent connection modules;

- Panels in various formats (portrait or landscape, 4:3 or 16:9);

- Battery-buffered SRAM (retain data);

- Battery-buffered real-time clock;

- Data evaluation with Jumo smartWARE;

- Evaluation (as of system version 6).

Advantages

- High speed performance;

- Flexible operating philosophy;

- Modern communication interfaces (e.g. OPC UA, MQTT);

- Integration of different fieldbus protocols such as PROFINET IO, EtherCAT, and Modbus-TCP/-RTU;

- Easy integration of new software functions via PLC (CODESYS V3.5);

- Availability of function and visualization libraries (as of system version 6);

- Easy adaptation of hardware inputs and outputs;

- Customized operation and visualization with several operator stations via CODESYS remote target visualization or via web visualization (mixed operation is possible);

- Jumo Web Cockpit.

Industries

- Process automation;

- Oven construction;

- Machine construction;

- Any process industry.

F.Fonseca is the representative of Jumo in Portugal.

Related products

- 0

- 1