Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Industrial Automation

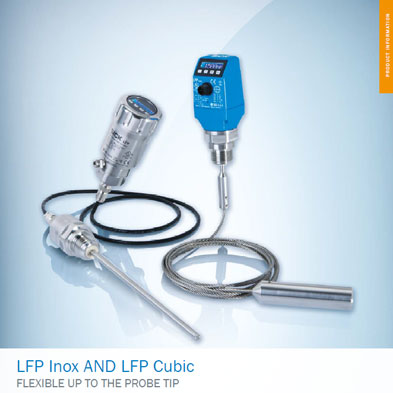

Level sensor TDR for food & beverage industry - LFP Inox – SICK

The LFP from SICK is a hygienic level sensor for liquids using TDR technology – a process for determining the time of flight of electromagnetic waves.

The time difference between the sent pulse and the reflected pulse is used to generate a level signal, both as a continuous value (analog output) and a freely positionable switching point (switching output). The use of robust FDA-compliant materials like stainless steel in an EHEDG-certified design means that the LFP guarantees optimal, unrestricted cleaning, even for the highest hygiene requirements. Its modular connection system allows simple and flexible installation in any application. Thanks to high temperature and pressure resistance, unrestricted use is possible under CIP and SIP conditions. The communication capability via IO-Link to the superordinate control units rounds off the profile.

The time difference between the sent pulse and the reflected pulse is used to generate a level signal, both as a continuous value (analog output) and a freely positionable switching point (switching output). The use of robust FDA-compliant materials like stainless steel in an EHEDG-certified design means that the LFP guarantees optimal, unrestricted cleaning, even for the highest hygiene requirements. Its modular connection system allows simple and flexible installation in any application. Thanks to high temperature and pressure resistance, unrestricted use is possible under CIP and SIP conditions. The communication capability via IO-Link to the superordinate control units rounds off the profile.

more details

Downloads

Request Offer

Features

Advantages

Industries

Ref. A01116025

F.Fonseca is the representative of SICK in Portugal.

- Level monitoring in hygienic applications;

- Manually retractable monoprobe up to 2,000 mm long;

- Polished surface with Ra < 0.8 µm;

- Process temperature up to 150 °C;

- Process pressure up to 16 bar;

- CIP/SIP resistant;

- High enclosure rating IP 67 and IP 69K;

- Interchangeable hygienic process connections;

- 3-in-1: combined display, analog output and binary output;

- Analog output 4…20 mA / 0…10 V, switchable, plus two transistor outputs;

- IO-Link communication;

- FDA-conformation, EHEDG-certification.

Advantages

- Robust design increases service life;

- High flexibility due to retractable probe and interchangeable connection concept;

- Cost savings thanks to multiple output signals: one system for level detection and continuous level monitoring;

- Maintenance-free and quick to commission, saving time and costs;

- No medium calibration or later recalibration required for commissioning, thus saving time and costs.

Industries

- Level monitoring in buffer tanks of filling systems and filling machines;

- Level control in rinsing systems;

- Level detection in CIP systems;

- Level monitoring in cosmetic, pharmaceutical mixing systems;

- Level measurement in industrial processes with difficult ambient conditions.

Ref. A01116025

F.Fonseca is the representative of SICK in Portugal.

Related products

- 0

- 1