Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Industrial Automation

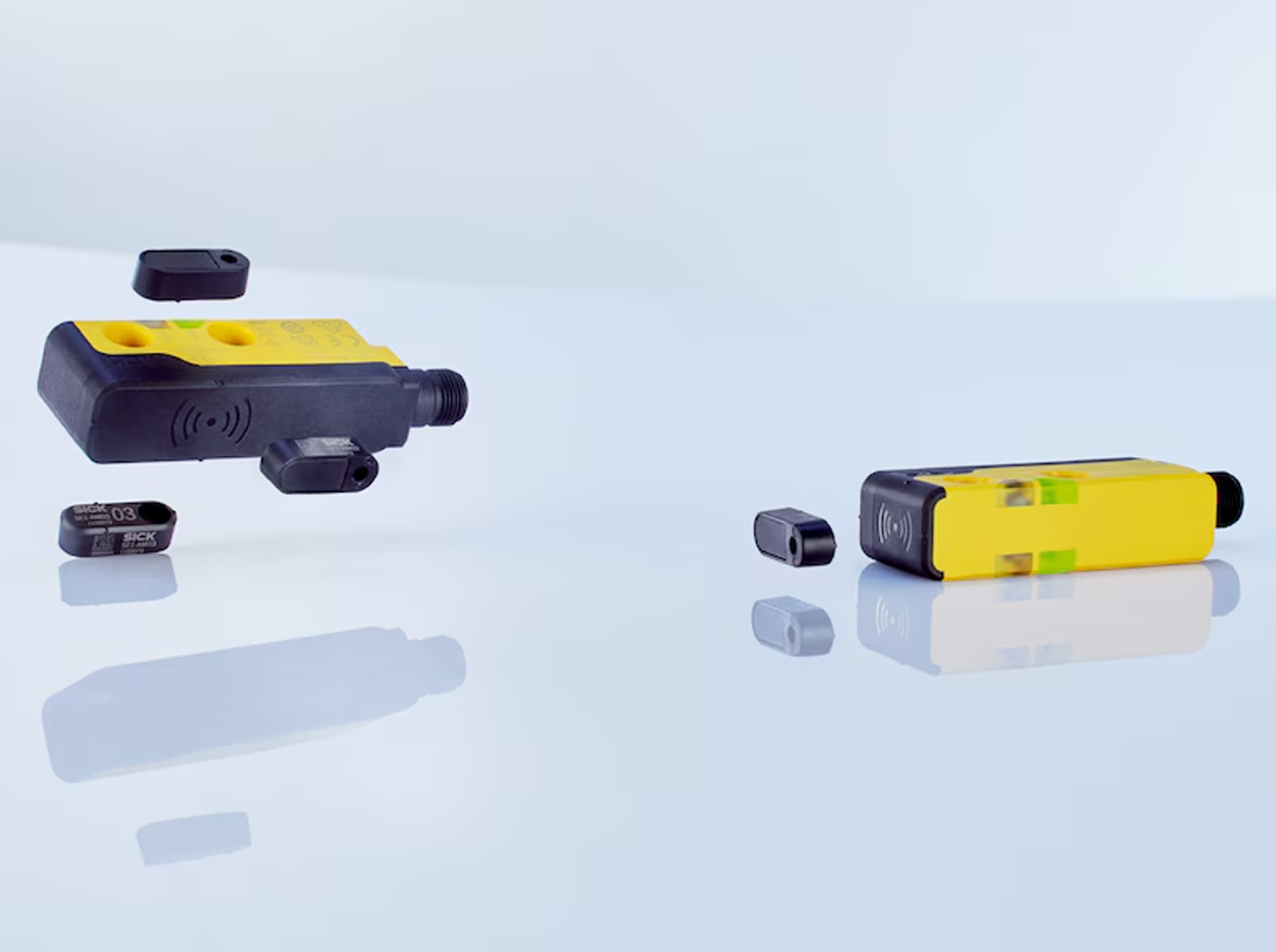

Non-contact safety sensor safeIDS - SICK

The safeIDS RFID from SICK is a safety sensor that provides a high degree of flexibility in manufacturing processes, supporting applications up to Performance Level e. When used together with an IO-Link Safety master and a safety controller, safeIDS enables safe object identification and reliable position detection.

The device is designed for quick installation and straightforward commissioning. Through its IO-Link Safety communication interface, it delivers not only safe identification data but also continuous diagnostic information. This enables rapid process changes with automatic machine restart. As a result, highly adaptable production – even down to batch size 1 – can be achieved, for example, in robotic applications.

The device is designed for quick installation and straightforward commissioning. Through its IO-Link Safety communication interface, it delivers not only safe identification data but also continuous diagnostic information. This enables rapid process changes with automatic machine restart. As a result, highly adaptable production – even down to batch size 1 – can be achieved, for example, in robotic applications.

more details

Downloads

Request Offer

Features

Advantages

Applications

F.Fonseca is the representative of SICK in Portugal.

- Safe RFID-based identification up to Performance Level e;

- Secure transmission of safe data via IO-Link Safety;

- Simple wiring concept using a standard 4-pin M12 cable;

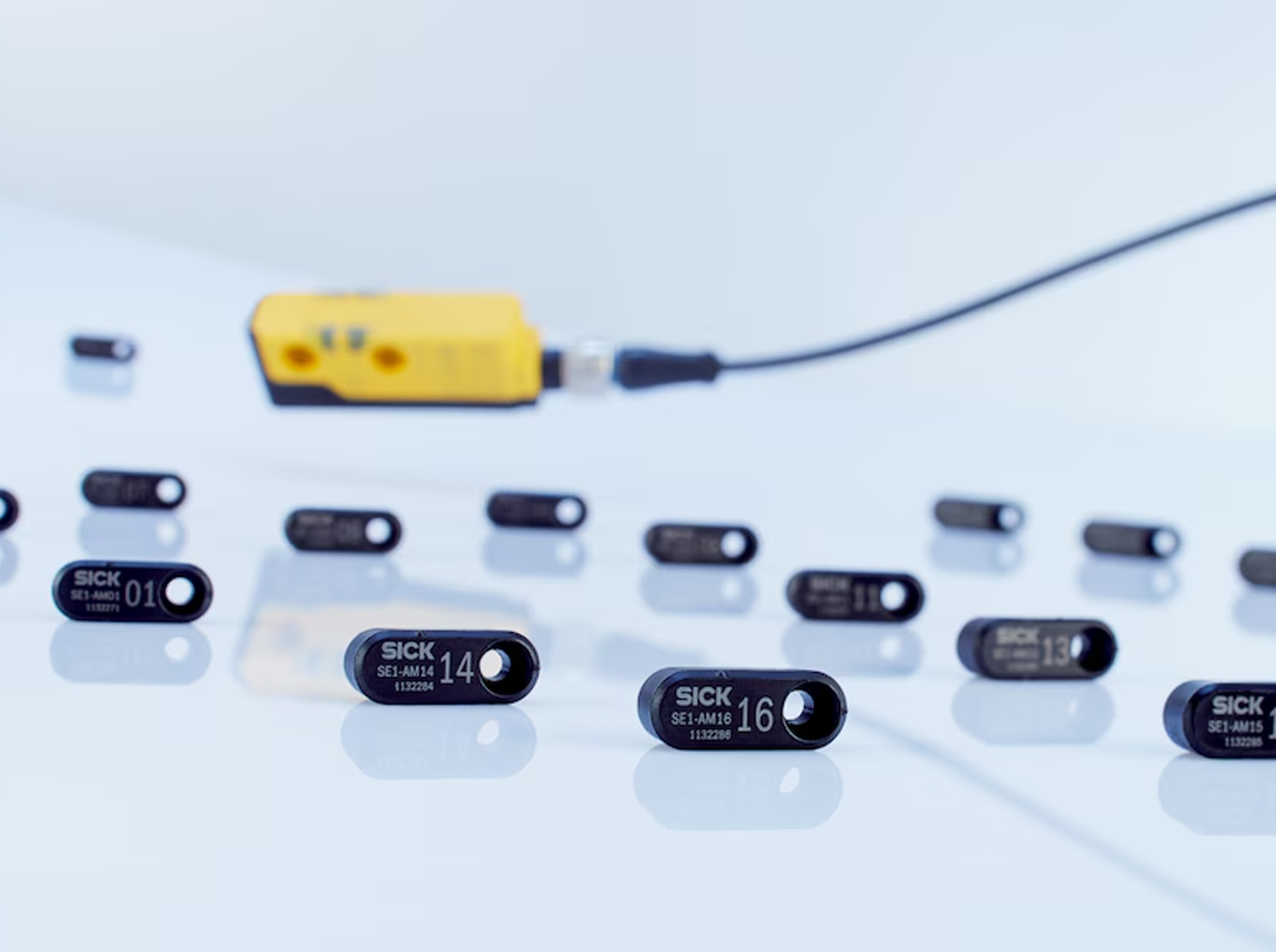

- Ability to detect more than 1,000 uniquely coded RFID tags;

- 16 pre-numbered tags available for fast installation and commissioning;

- Compact housing with lateral or frontal actuation for flexible mounting.

Advantages

- Safe and flexible object identification up to PL e: Reliable detection and differentiation of objects, workpieces, and tools using RFID and IO-Link Safety – enabling automatic adaptation of safety parameters and reducing manipulation risks;

- Fast, fully automatic process changes: Automatic machine restart and recognition of over 1,000 unique tags eliminate manual confirmations, supporting high productivity and rapid format or tool changes;

- Easy installation and seamless integration: Simple wiring with a standard 4-pin M12 cable and quick commissioning with numbered tags. IO-Link Safety ensures smooth integration into all major fieldbus systems;

- Continuous safe and non-safe data for efficient control: IO-Link Safety transmits safe identification data and diagnostics over a single cable, reducing wiring effort while enabling better process transparency and optimized machine control;

- High application flexibility: Available with lateral or frontal actuation, safeIDS is easy to mount and suitable for diverse machine modules, robotic applications, and production environments – even down to batch size 1;

- Safe position detection for material handling: Precise tag-based verification of correct vehicle or workpiece position ensures safe and reliable material transfer.

Applications

- Automatic tool change in robot applications;

- Feed monitoring on processing robots;

- Monitoring the material feed at automated workstations;

- Transfer of loads at transport stations.

F.Fonseca is the representative of SICK in Portugal.

- 0

- 1