Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Process, Instrumentation & Environment

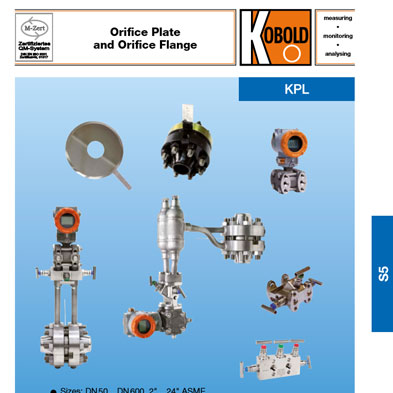

Orifice plate and Orifice flange KPL - Kobold

If a pipeline (through which a medium flows) is reduced at a particular point by a cross-sectional constriction, the flow speed of the measured medium is increased at that point. According to Bernoulli’s energy equation and the law of continuity, the total flow head (dynamic velocity head and static pressure head) is constant. The increase in speed at the constriction causes a reduction in the static head.

The resulting pressure drop is called the differential pressure head; it is a measure of the flow (volume per unit of time or mass per unit of time). The flow rate q is given by: q = c√∆p The flow rate (q) is a function of the square root of the differential pressure head (∆p), where c is the coefficient of flow rate determined by the shape of the differential pressure transducer and the operating data. The pipeline may be constricted with orifice plates.

The resulting pressure drop is called the differential pressure head; it is a measure of the flow (volume per unit of time or mass per unit of time). The flow rate q is given by: q = c√∆p The flow rate (q) is a function of the square root of the differential pressure head (∆p), where c is the coefficient of flow rate determined by the shape of the differential pressure transducer and the operating data. The pipeline may be constricted with orifice plates.

more details

Downloads

Request Offer

Primary Elements – Proven Flow Measurement Technology

Primary elements such as orifice plates or orifice flanges are suitable for flow measurement of liquids, gases and steam. This operating principle has been in use for many decades.

The differential pressure (DP) transmitter required for flow measurement may be easily exchanged after installation in combination with a manifold valve.

The orifice plates or orifice flanges are available in sizes from DN 50 (2”) to DN 600 (24”) and as compact or remote version.

In compact version the primary element, the manifold valve, the condensate pot (necessary for steam flow measurement) and the differential pressure (DP) transmitter type PAD are supplied as a single unit. This design is space saving and may be used for steam flow measurement up to a maximum temperature of +300 °C.

In remote version the differential pressure (DP) transmitter and the primary element are mounted separately and are connected with an appropriate impulse tubing by the customer, enabling a flow measurement with maximum temperatures up to +500 °C.

The various designs and process connections allow usage with numerous mounting positions. The calculation of primary elements is according to globally standardized norm ISO 5167. Other standards are also available on request.

Features

Advantages

Industries

F.Fonseca is the representative of Kobold in Portugal.

Primary elements such as orifice plates or orifice flanges are suitable for flow measurement of liquids, gases and steam. This operating principle has been in use for many decades.

The differential pressure (DP) transmitter required for flow measurement may be easily exchanged after installation in combination with a manifold valve.

The orifice plates or orifice flanges are available in sizes from DN 50 (2”) to DN 600 (24”) and as compact or remote version.

In compact version the primary element, the manifold valve, the condensate pot (necessary for steam flow measurement) and the differential pressure (DP) transmitter type PAD are supplied as a single unit. This design is space saving and may be used for steam flow measurement up to a maximum temperature of +300 °C.

In remote version the differential pressure (DP) transmitter and the primary element are mounted separately and are connected with an appropriate impulse tubing by the customer, enabling a flow measurement with maximum temperatures up to +500 °C.

The various designs and process connections allow usage with numerous mounting positions. The calculation of primary elements is according to globally standardized norm ISO 5167. Other standards are also available on request.

Features

- Connection: DN 50…600;

- Material: steel, st. St., Hastelloy C, Titanium, Monel, Tantalum;

- Max. pressure: PN 420;

- Max. temperature: +500 °C.

Advantages

- No maintenance;

- Economical and reliable.

Industries

- Flow measurement of liquids, gases or steam in all industries.

F.Fonseca is the representative of Kobold in Portugal.

- 0

- 1