This Tuesday Carnival, 21/02, we’re closed! 🎭

Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Industrial Automation

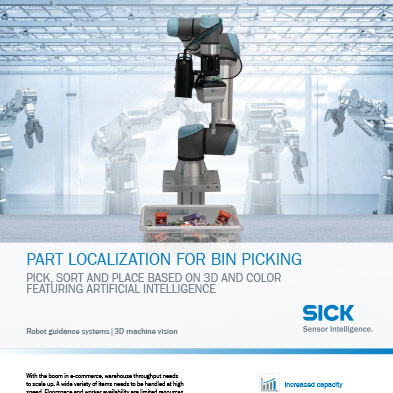

Part localization for bin picking - SICK

Pick, sort and place based on 3d and color featuring artificial intelligence.

Robot guidance systems | 3D machine vision: with the boom in e-commerce, warehouse throughput needs to scale up. A wide variety of items needs to be handled at high speed. Floorspace and worker availability are limited resources.

Fully automated picking robots help to increase pick-and-place accuracy and speed with 24/7 uptime and only a small footprint.

Robot guidance systems | 3D machine vision: with the boom in e-commerce, warehouse throughput needs to scale up. A wide variety of items needs to be handled at high speed. Floorspace and worker availability are limited resources.

Fully automated picking robots help to increase pick-and-place accuracy and speed with 24/7 uptime and only a small footprint.

more details

Downloads

Request Offer

SICK offers a high-precision robot guidance system for localizing items to be picked. A high-resolution, high-speed camera detects a wide range of objects of different shapes and colors.

Automatic detection of all kinds of objects and colors

Zivid Two 3D camera

• High dynamic range (HDR) technology for challenging applications with reflective and shiny objects;

• Robot-mounted for localization of items in multiple bins;

• Color distinction to identify and sort objects of similar shape;

• Accurate picking thanks to high precision 3D point cloud.

Powerful, user-friendly software

Machine learning /AI

• Train new scenarios using dStudio from SICK;

• Classification of a wide range of objects.

Software plug-in concept

• Modification of functions possible at any time;

• Localization based on geometrical surface features; no CAD matching required.

Easy robot programming

Robot programming

• Autonomous robot motion planning thanks to integration with third-party library.

F.Fonseca is the representative of SICK in Portugal.

- Increased capacity;

- Less manual work;

- Faster order processing.

Automatic detection of all kinds of objects and colors

Zivid Two 3D camera

• High dynamic range (HDR) technology for challenging applications with reflective and shiny objects;

• Robot-mounted for localization of items in multiple bins;

• Color distinction to identify and sort objects of similar shape;

• Accurate picking thanks to high precision 3D point cloud.

Powerful, user-friendly software

Machine learning /AI

• Train new scenarios using dStudio from SICK;

• Classification of a wide range of objects.

Software plug-in concept

• Modification of functions possible at any time;

• Localization based on geometrical surface features; no CAD matching required.

Easy robot programming

Robot programming

• Autonomous robot motion planning thanks to integration with third-party library.

F.Fonseca is the representative of SICK in Portugal.

- 0

- 1