Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Industrial Automation

Collaborative robot TM5 – Techman Robot

TM5 - The world’s first collaborative robot with built-in vision.

The Techman’s TM5 collaborative robot features simple programming, innovative integrated vision capabilities together with the latest safety functionality, all leading to rapid deployment in a huge variety of applications.

Having vision identification functionality completely integrated within the TM5 cobot platform, provides an easy and intuitive way to achieve robot calibration to work piece or tooling, product selection, 1D or 2D barcodes and a host of other vision applications, delivering a true Industry 4.0 solution.

The Techman’s TM5 collaborative robot features simple programming, innovative integrated vision capabilities together with the latest safety functionality, all leading to rapid deployment in a huge variety of applications.

Having vision identification functionality completely integrated within the TM5 cobot platform, provides an easy and intuitive way to achieve robot calibration to work piece or tooling, product selection, 1D or 2D barcodes and a host of other vision applications, delivering a true Industry 4.0 solution.

more details

Downloads

Request Offer

SMART

Built-in vision system

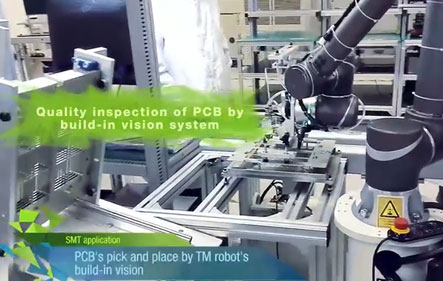

TM Robot is equipped with a built-in vision system, which integrates into both the hardware and software perfectly, whereas traditional add-on vision solutions to robotics are complicated, time consuming and costly to implement.

Masters in robot vision

Many standard cobots vision functions are already built into our system: pattern matching, object localisation, image enhancement, bar code reading, colour recognition, etc. All these functions have been integrated into our remarkably easy-to-use user interface.

5 Minutes to achieve a visual pick & place task

Combining our smart vision system and our hand-guiding functions, everyone, even those without robotic programming experience, can achieve a visual pick & place task within 5

minutes.

SIMPLE

Revolutionary user interface

No more coding! You can implement your automation task with our revolutionary simple-to-use user interface, an all-graphic flow chart based HMI. Users, even those without coding experience with industrial robots, can learn to use TM robot easily and quickly. You can program every built-in vision function on the GUI. Furthermore, the traditional heavy umbilical wired pendant is gone. Our user interface can be operated on PCs, notebooks or tablets.

Use your hand

Another reason TM Robot is simpler to program than the other modern robots are our well-designed hand-guiding functions with servo assist. You can lock selected axes to allow adjustment in defined planes and then fine tune the co-ordinates with easy editing of those co-ordinates within the programming package.

Easy to deploy

Because TM robot is so simple to program, it is very easily deployed into different applications, reducing your time-to-production and saving your total cost in automation.

SAFE

Force limiting

TM Robot complies with the ISO 10218-1 & ISO/TS 15066 human-robot co-operation safety requirements for cobot, allowing the robot to be programmed with both speed and force limits.

Safety is our priority

TM Robot is serious about safety in every aspect of the design of the whole cobot system, through hardware, software and operational design.

Ergonomic design

TM cobots are physically designed to be safe to their surroundings, soft end caps and no sharp edges are all part of the collaborative experience.

Features

Advantages

Industries

F.Fonseca is the representative of Techman Robot in Portugal.

Built-in vision system

TM Robot is equipped with a built-in vision system, which integrates into both the hardware and software perfectly, whereas traditional add-on vision solutions to robotics are complicated, time consuming and costly to implement.

Masters in robot vision

Many standard cobots vision functions are already built into our system: pattern matching, object localisation, image enhancement, bar code reading, colour recognition, etc. All these functions have been integrated into our remarkably easy-to-use user interface.

5 Minutes to achieve a visual pick & place task

Combining our smart vision system and our hand-guiding functions, everyone, even those without robotic programming experience, can achieve a visual pick & place task within 5

minutes.

SIMPLE

Revolutionary user interface

No more coding! You can implement your automation task with our revolutionary simple-to-use user interface, an all-graphic flow chart based HMI. Users, even those without coding experience with industrial robots, can learn to use TM robot easily and quickly. You can program every built-in vision function on the GUI. Furthermore, the traditional heavy umbilical wired pendant is gone. Our user interface can be operated on PCs, notebooks or tablets.

Use your hand

Another reason TM Robot is simpler to program than the other modern robots are our well-designed hand-guiding functions with servo assist. You can lock selected axes to allow adjustment in defined planes and then fine tune the co-ordinates with easy editing of those co-ordinates within the programming package.

Easy to deploy

Because TM robot is so simple to program, it is very easily deployed into different applications, reducing your time-to-production and saving your total cost in automation.

SAFE

Force limiting

TM Robot complies with the ISO 10218-1 & ISO/TS 15066 human-robot co-operation safety requirements for cobot, allowing the robot to be programmed with both speed and force limits.

Safety is our priority

TM Robot is serious about safety in every aspect of the design of the whole cobot system, through hardware, software and operational design.

Ergonomic design

TM cobots are physically designed to be safe to their surroundings, soft end caps and no sharp edges are all part of the collaborative experience.

Features

- Payload: 6kg/4kg;

- Reach: 700mm/900mm;

- Repeatability: +/- 0,05mm;

- I/O ports: 16 digital inputs and 16 digital outputs, 2 analogue inputs and 1 analogue output;

- I/O interfaces: 3×COM, 1×HDMI, 1×EtherCAT, 2×GigE, 1×LAN, 4×USB2.0, 2×USB3.0, 1×VGA;

- Power consumption: Max. 1300W;

- Power supply: 100-240 VAC, 50-60 Hz;

- Robot vision (Eye in Hand – built-in): 1.2M/5M pixels, colour camera.

Advantages

- Smart, simple, safe;

- Human-machine cooperation;

- Smart and flexible;

- Ultra-low maintenance.

Industries

- Automotive;

- Electronics;

- Food & Beverage;

- Logistics;

- Machinery;

- Metal processing;

- Textiles.

F.Fonseca is the representative of Techman Robot in Portugal.

Related products

- 0

- 1