Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Industrial Automation

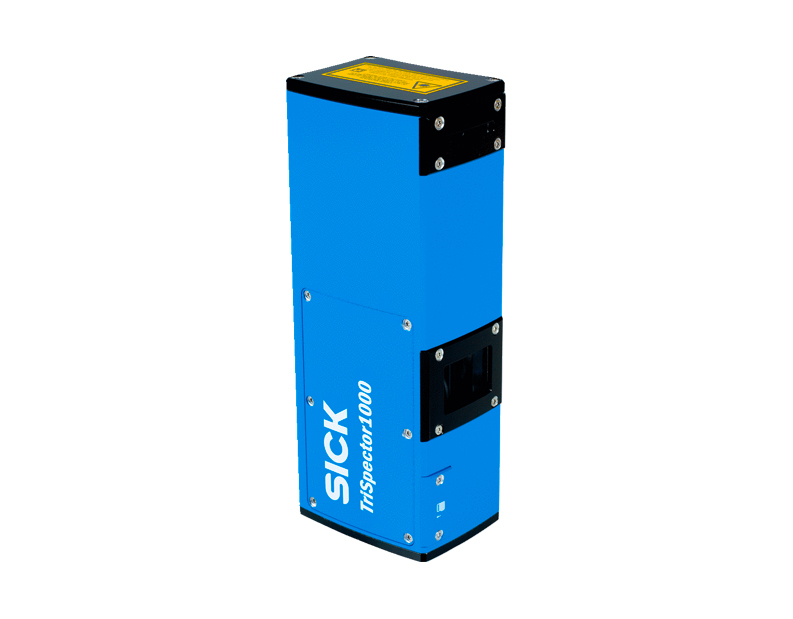

Vision Sensor 3D TriSpector1000 – SICK

Intuitive 3D inspection.

The TriSpector1000, from SICK, is a stand-alone configurable sensor for cost-efficient 3D inspections. No matter what the shape, color or orientation of the product, the sensor is up to the challenge.

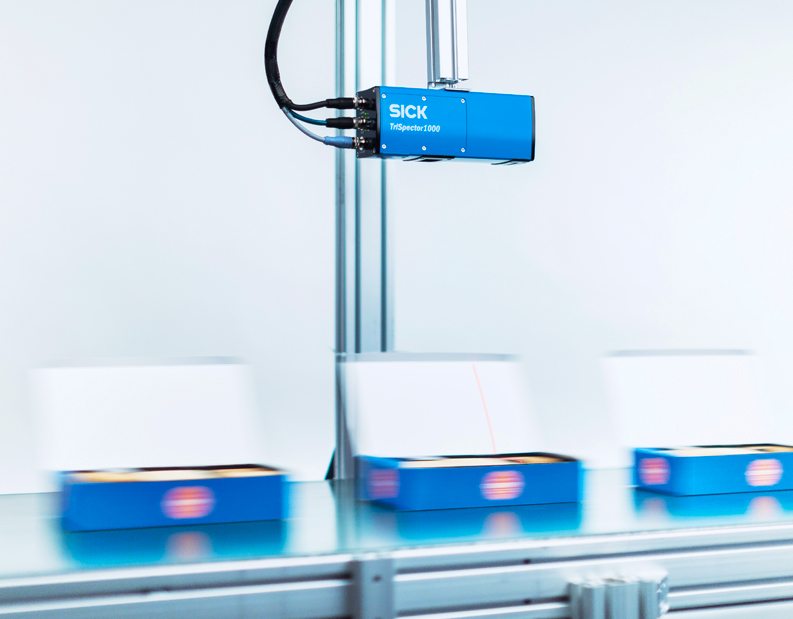

Now content, completeness and emptiness can be verified in all dimensions. It is perfectly suited for solving quality control applications in the consumer goods and packaging industry.

The TriSpector1000, from SICK, is a stand-alone configurable sensor for cost-efficient 3D inspections. No matter what the shape, color or orientation of the product, the sensor is up to the challenge.

Now content, completeness and emptiness can be verified in all dimensions. It is perfectly suited for solving quality control applications in the consumer goods and packaging industry.

more details

Downloads

Request Offer

Thanks to its intuitive user interface, the SICK vision sensor TriSpector1000 ensures easy commissioning and operation. Even quick device replacement is easy with guaranteed field of view and re-use of saved settings.

Features

Advantages

Industries

F.Fonseca is the representative of SICK in Portugal.

Features

- 3D inspection of moving parts;

- Intuitive user interface;

- Embedded image analysis;

- Easy replacement concept;

- High resolution 3D image with intensity overlay;

- Factory calibrated 3D data, true mm values in all dimensions;

- Rugged IP67 metal housing with plastic windows.

Advantages

- Reliable 3D inspection even when part color, position and height varies;

- Easy commissioning and operation thanks to an intuitive user interface;

- Embedded image analysis for fast configuration;

- Quick device replacement due to guaranteed field of view and re-use of saved settings;

- Intensity data enhances 3D navigation, allows checking presence of label, printed pattern or object rotation;

- Factory calibrated data simplifies setup and reduces time and effort;

- Withstands harsh or food processing environments.

Industries

- Quality control in consumer goods, volume and thickness measuring, counting and positioning of objects;

- Box integrity including content verification, completeness and emptiness check;

- Product dimensioning in food processing.

F.Fonseca is the representative of SICK in Portugal.

- 0

- 1