Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Industrial Automation

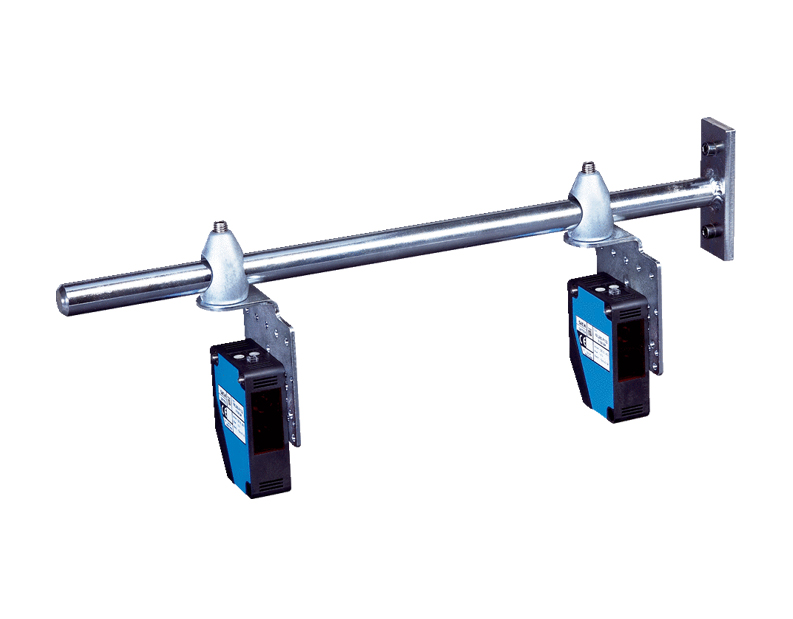

Muting kits and accessories - SICK

Automated material transportation into and out of hazardous areas can be secured via a variety of solutions in order to avoid hazards to people and to ensure productivity.

Securing a machine with a muting system, comprising a protective device combined with muting sensors (e.g., photoelectric retro-reflective sensors). The placement of the muting sensors means that the material to be transported is detected as such and the protective device is given a time limit and bridged depending on the process. People are safely detected.

Securing a machine with a muting system, comprising a protective device combined with muting sensors (e.g., photoelectric retro-reflective sensors). The placement of the muting sensors means that the material to be transported is detected as such and the protective device is given a time limit and bridged depending on the process. People are safely detected.

more details

Downloads

Request Offer

Features

Advantages

Industries

F.Fonseca is the representative of SICK in Portugal.

- Different sensor technologies to match the application needs;

- Various mounting devices that enable the installation directly in the device column or in the optoelectronic device.

Advantages

- A rise in productivity, as maximum material flow is ensured thanks to reliable human-material differentiation;

- High flexibility for process adaptation through additional functionalities in the protective device;

- Higher flexibility through the detection of geometric object shapes by the light curtain solution;

- Lower overall costs for the light curtain solution through the reduction of the maintenance costs, savings on additional sensors, and lower amounts of wiring work;

- Standardization, as only two material numbers are needed for the light curtain solution.

Industries

- All applications in which an automated material flow occurs and persons could be endangered by machine movement;

- Automotive industry;

- Wood industry;

- Consumer goods industry;

- Storage and conveyor.

F.Fonseca is the representative of SICK in Portugal.

- 0

- 1