Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Industrial Automation

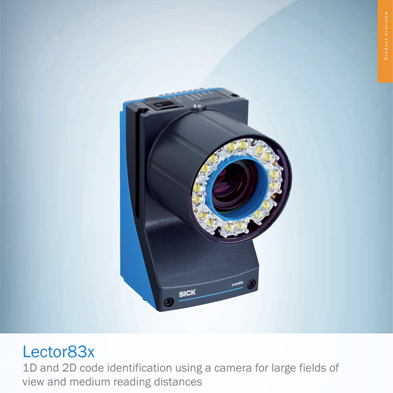

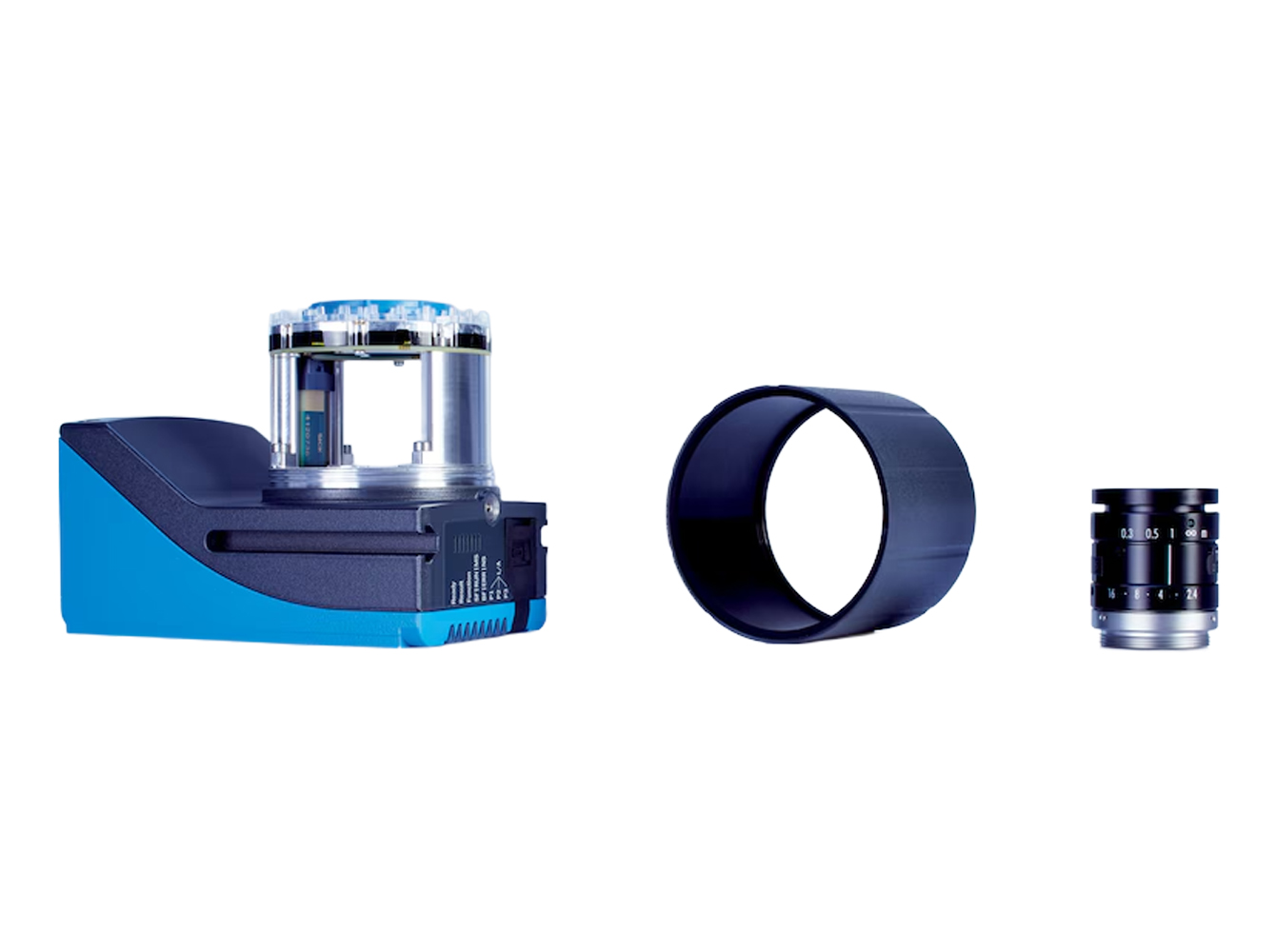

Image-based code reader Lector83x – SICK

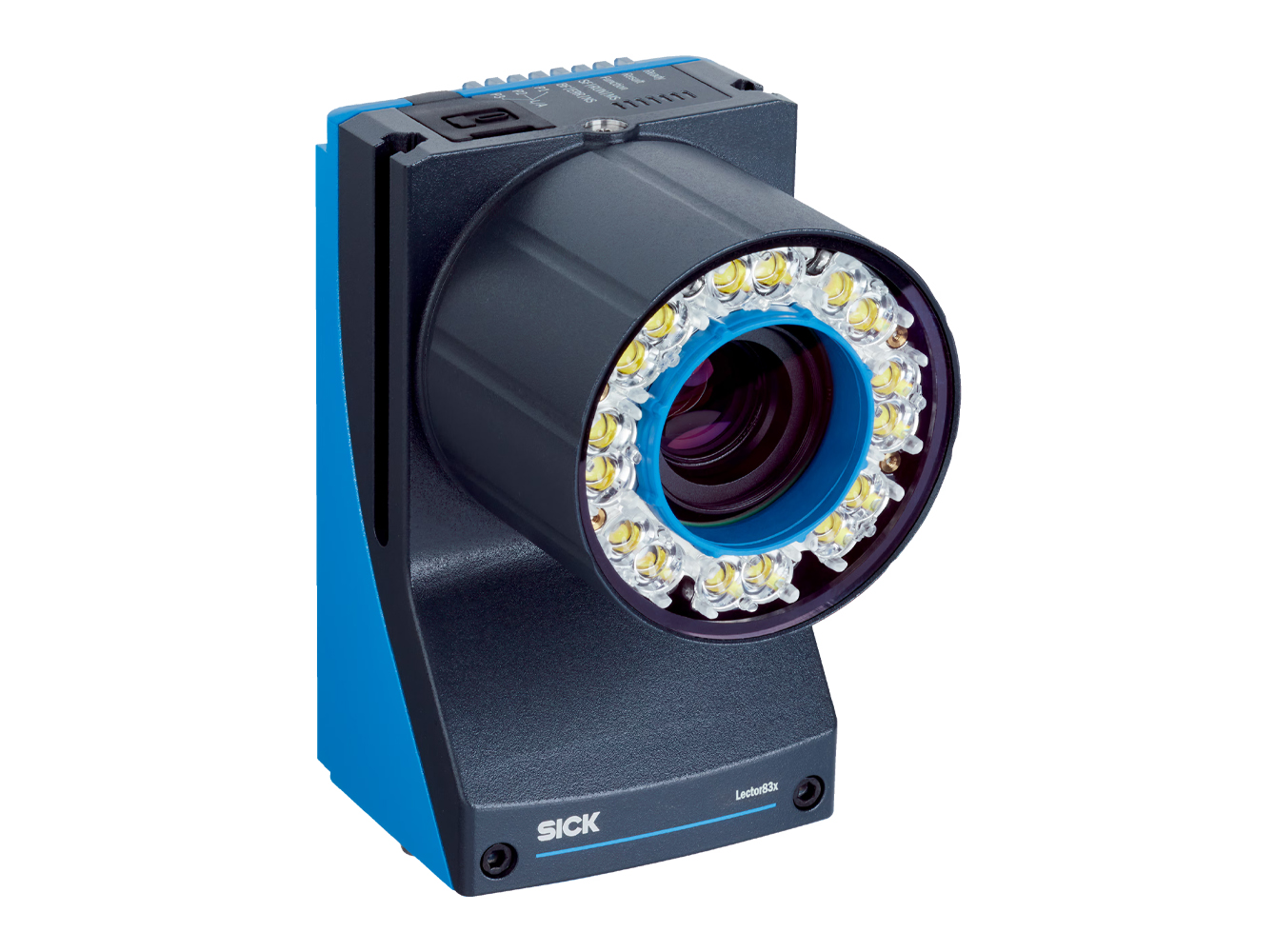

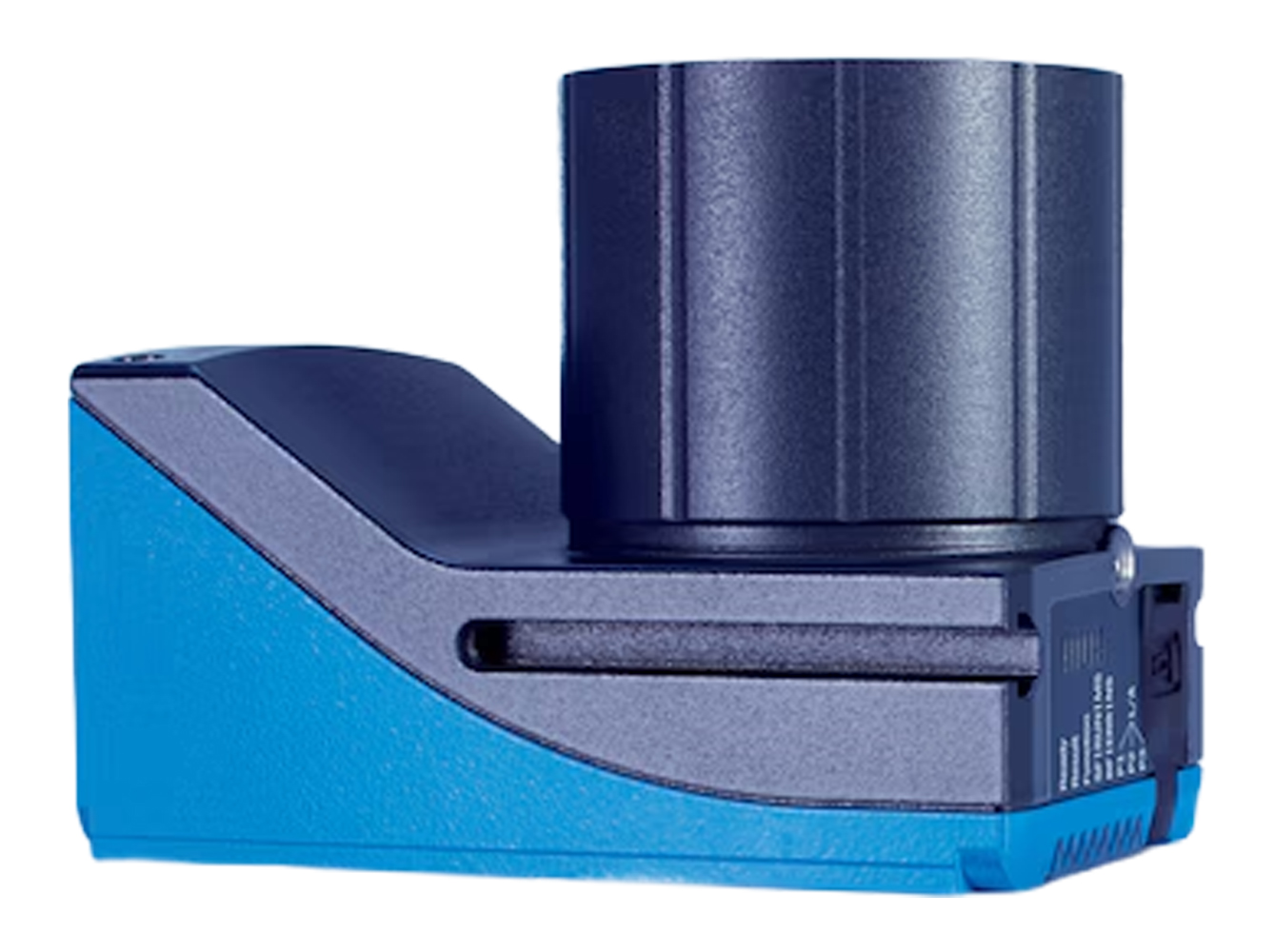

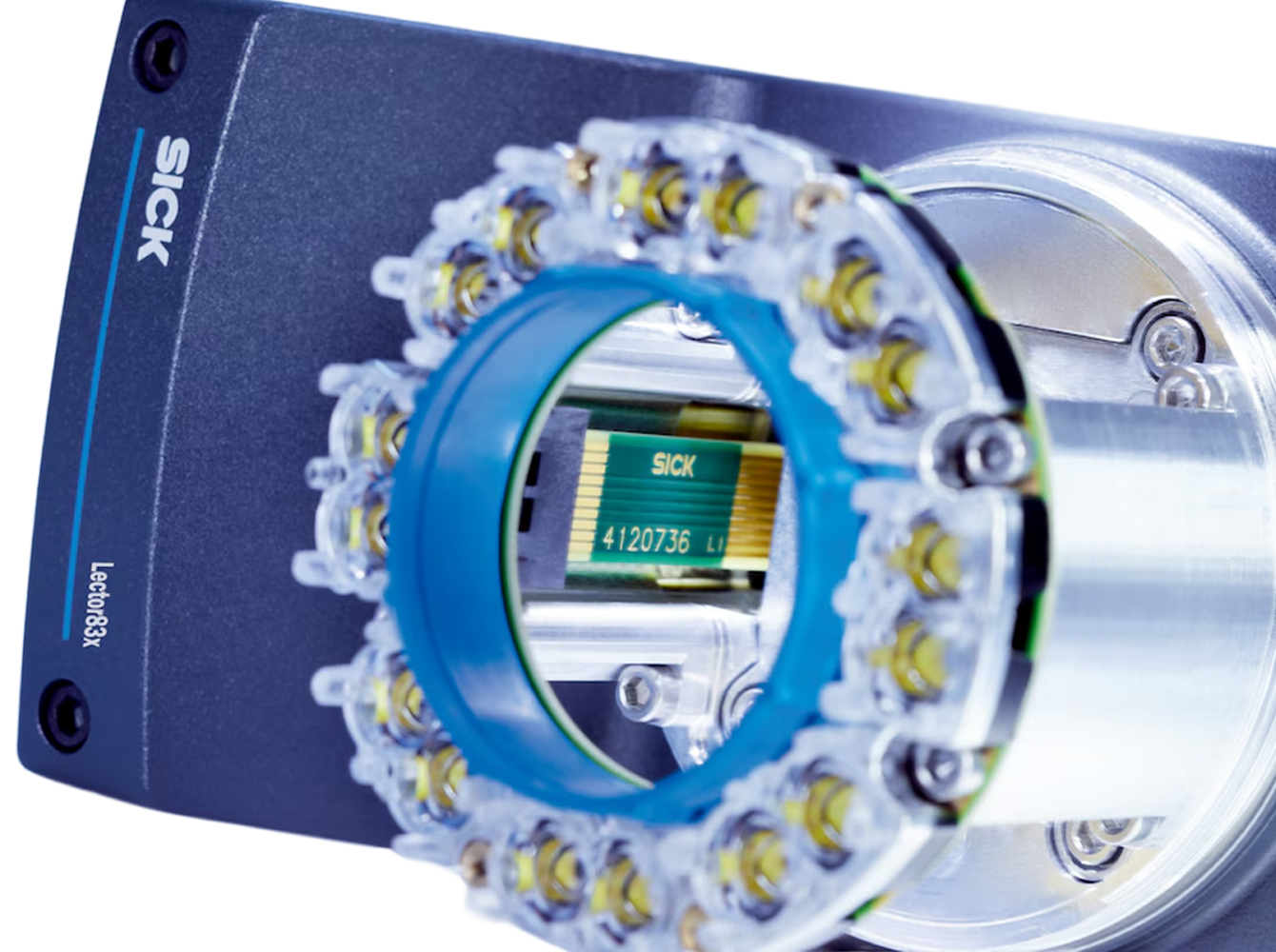

The Lector83x image-based code reader from SICK offers high reading performance at medium reading distances and is easy to integrate into industrial networks. The compact camera has a resolution of 3 or 5 megapixels, a large depth-of-field control, and a wide field of view. In addition to high-performance multi-core processing, dual-port fieldbus, and multiple interfaces, the compact design reduces the number of required devices and installation effort at reading stations.

Using AI-based segmentation, the camera also identifies damaged codes at conveyor speeds of up to 2.5 m/s and correctly assigns them to objects. The Lector83x can be intuitively configured using a web server and is ready for use within a few minutes – even without specialist knowledge.

Using AI-based segmentation, the camera also identifies damaged codes at conveyor speeds of up to 2.5 m/s and correctly assigns them to objects. The Lector83x can be intuitively configured using a web server and is ready for use within a few minutes – even without specialist knowledge.

more details

Downloads

Request Offer

Features

Advantages

Applications

F.Fonseca is the representative of SICK in Portugal.

- AI-based segmentation, superresolution, multi-core CPU;

- Large depth-of-field, and wide field of view;

- Resolution of 3 or 5 megapixels with various lenses and different illumination colors;

- Intuitive application-based configuration via web server;

- Three-dimensional assignment of codes to objects;

- Ethernet-based industrial communication interfaces (e.g. PROFINET, EtherNet/IP);

- Dual-port fieldbus and DIOs.

Advantages

- High camera resolution for precise reading and evaluation of even small codes on large surfaces;

- High sorting rate and less manual rework thanks to the high read rate, regardless of the code quality;

- High-performance decoder and processor for high throughput with short working distances;

- Flexible integration into industrial networks and PLCs via Ethernet-based fieldbuses;

- Easy commissioning thanks to the intuitive application;

- High flexibility in a small space: coverage of large areas with a single camera – a small number of devices and components required.

Applications

- Automotive: tire identification;

- CEP industry: identification (e.g., for letters, parcels, flats);

- Packaging industry: multi-code identification on primary and secondary packaging;

- Retail and warehousing: identification in sorting and picking processes, recording of incoming and outgoing goods.

F.Fonseca is the representative of SICK in Portugal.

- 0

- 1