Login

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registryLogin

MyFFonseca

If you do not have an account MyFFonseca, please register and get access to exclusive content to registered users!

Create registry

Color sensor CSS – SICK

The CSS color sensors from SICK combine high color resolution and high-speed color detection in a versatile product range designed for demanding industrial applications.

Both product families support IO-Link, enabling transfer and external storage of up to 24 colors per identification task (job), and can be quickly commissioned using the application-specific setup assistant in SOPAS software.

Both product families support IO-Link, enabling transfer and external storage of up to 24 colors per identification task (job), and can be quickly commissioned using the application-specific setup assistant in SOPAS software.

Contrast sensor Glare - SICK

The Contrast Glare sensor is specially designed to recognize and differentiate objects on the basis of their gloss in order to control production processes.

The Glare sensor from SICK analyzes the spatial distribution of reflected light using Delta-S technology, which allows the sensor to determine the gloss level of flat object surfaces and to differentiate between objects of differing gloss levels. The measurement result is transmitted to the process controls either via two digital switching outputs or IO-Link.Several operating modes are available, making the Glare sensor perfectly suited to a range of different applications.

The Glare sensor from SICK analyzes the spatial distribution of reflected light using Delta-S technology, which allows the sensor to determine the gloss level of flat object surfaces and to differentiate between objects of differing gloss levels. The measurement result is transmitted to the process controls either via two digital switching outputs or IO-Link.Several operating modes are available, making the Glare sensor perfectly suited to a range of different applications.

Contrast sensors KTS and KTX – SICK

Where most of the contrast sensors reach their limits, the KTS and KTX offer more applications, more areas of use, more flexibility.

They incorporate more than just the reliability and availability of contrast sensors from the market and technology leader: TwinEye-Technology®, multifunctional display, integrated job memory and the combination of contrast and color sensor technology.

They incorporate more than just the reliability and availability of contrast sensors from the market and technology leader: TwinEye-Technology®, multifunctional display, integrated job memory and the combination of contrast and color sensor technology.

Fiber optic contrast sensors KTL180 – SICK

The KTL180 reliably detects contrast differences even at high machine speeds. Thanks to its 31.2 kHz switching frequency, a high grayscale resolution and manual switching threshold adjustment, the KTL180 makes for safe object detection.

The response time of 16 µs ensures stable and accurate detection of contrast differences, for example with print marks, even for high-gloss materials. The sensor can be quickly adjusted to the respective application with the 7-segment display and easy menu guidance. Various teach-in processes as well as an integrated job save increase the flexibility during commissioning in a large range of applications - with very high process stability.

The response time of 16 µs ensures stable and accurate detection of contrast differences, for example with print marks, even for high-gloss materials. The sensor can be quickly adjusted to the respective application with the 7-segment display and easy menu guidance. Various teach-in processes as well as an integrated job save increase the flexibility during commissioning in a large range of applications - with very high process stability.

Fork sensor UFW - SICK

The UFW fork sensor from SICK makes non-contact web edge guiding possible. Thanks to ultrasonic technology, the UFW detects various materials with great precision and is therefore ideally suited for applications with transparent films or light-sensitive materials. The compact housing designs (30 mm and 60 mm fork width) allow space-saving installation. Calibration is simple to perform using a teach-in button. Three LEDs indicate immediately the position of the web material within the fork. Furthermore, the IO-Link communication interface opens numerous possibilities for fine adjustment, analyses, and monitoring.

Fork sensor WFE – SICK

The WFE is a rugged fork sensor from SICK that is simple and easy to mount. Thanks to its reliability and accurate detection, it is suitable for a large number of applications. The WFE can precisely detect objects up to a size of 0.5 mm with a high switching frequency of 5 kHz. The sensitivity adjustment, a push-pull output, and the ability to select between light and dark switching make it flexible and convenient to use. The WFE is enclosed in a rugged hybrid housing (IP67) made from ABS plastic with a carbon steel frame and performs reliably even in harsh environments. Five different fork widths and several different types of connectors are available. The WFE is therefore well and truly an all-in-one fork sensor solution.

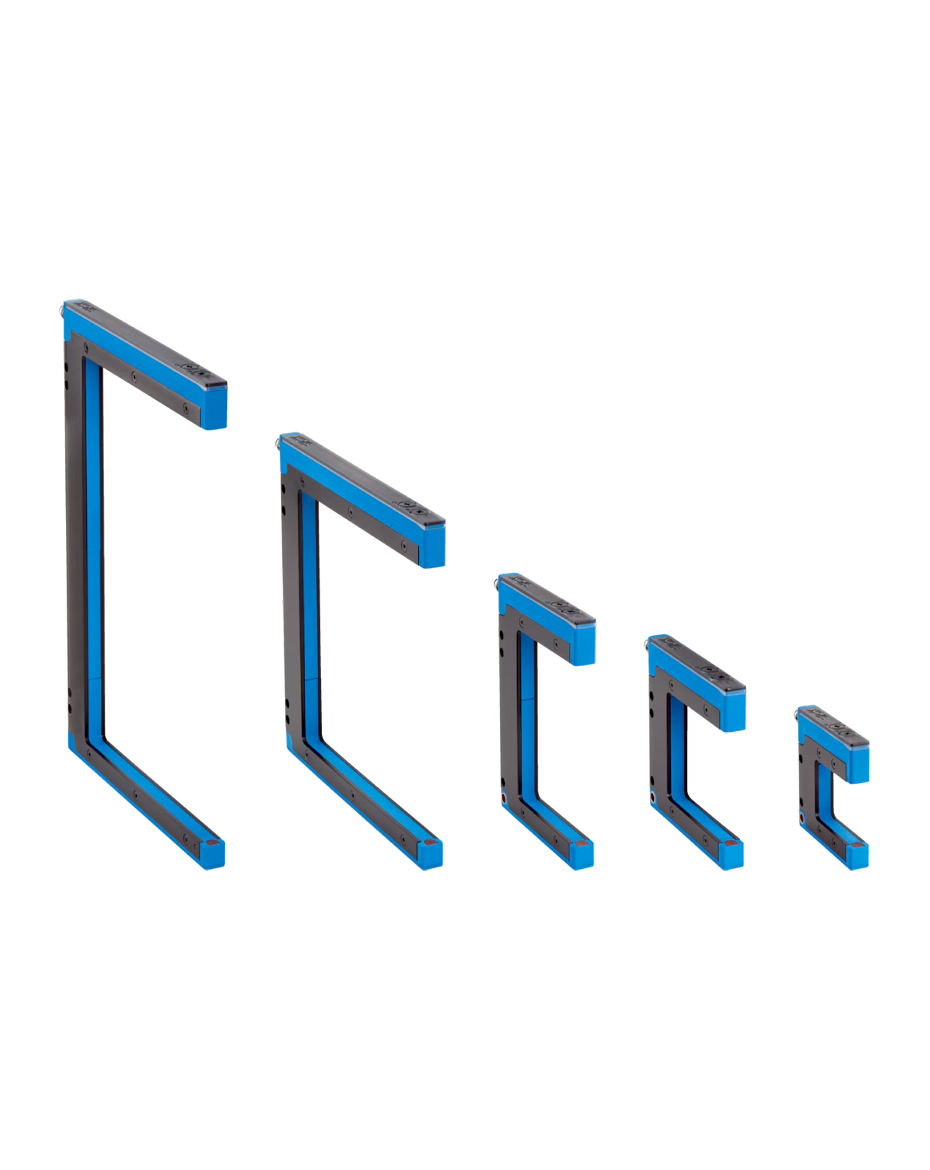

Fork sensors WF, UF, WFM e WFS - SICK

Simplicity, flexibility, and precision – combined in a single fork sensor.

SICK fork sensors combine senders and receivers in a single housing, meaning that they can be adjusted quickly.

Thanks to the precise, focused light beam and the high detection accuracy, the sensors from SICK also detect very minor light attenuation differences. Many different fork sizes, straightforward mounting, and exceptionally high ambient light immunity are just some of the advantages of these fork sensors.

SICK fork sensors combine senders and receivers in a single housing, meaning that they can be adjusted quickly.

Thanks to the precise, focused light beam and the high detection accuracy, the sensors from SICK also detect very minor light attenuation differences. Many different fork sizes, straightforward mounting, and exceptionally high ambient light immunity are just some of the advantages of these fork sensors.

Luminescence sensors LUT - SICK

The bright idea for fluorescent material!

Luminescence sensors from SICK detect visible and non-visible marks that illuminate when using ultraviolet (UV) light.

Fluorescent material and marks are reliably detected independently of their pattern, colors or surface conditions on any material. Luminescence sensors LUT from SICK emit UV light with a wave length of approximately 375 nm. Fluorescent substances convert the UV light into long-wave visible light, which is then received and evaluated by the luminescence sensor.

Luminescence sensors from SICK detect visible and non-visible marks that illuminate when using ultraviolet (UV) light.

Fluorescent material and marks are reliably detected independently of their pattern, colors or surface conditions on any material. Luminescence sensors LUT from SICK emit UV light with a wave length of approximately 375 nm. Fluorescent substances convert the UV light into long-wave visible light, which is then received and evaluated by the luminescence sensor.

Mini contrast sensor KTM - SICK

Top performance for universal, space-saving use in the packaging industry even under harsh conditions: The new KTM prime contrast sensor from SICK features a high grayscale resolution and is integrated into a small, tried-and-tested housing that is also available in stainless steel.

The optimized OES4 ASIC technology and a response time of 35 µs ensure reliable and accurate detection of contrast marks, even on glossy materials. The various teach-in methods (dynamic, static, and switching threshold near the marks) ensure greater flexibility during commissioning. The integrated IO-Link interface can be used to access the parameter settings. This speeds up and simplifies format changes. The KTM reliably detects marks even in conditions with weak contrast ratios and is therefore ideal for use in a wide range of applications, in the stainless-steel version, it can even be used in harsh environments during intensive cleaning.

The optimized OES4 ASIC technology and a response time of 35 µs ensure reliable and accurate detection of contrast marks, even on glossy materials. The various teach-in methods (dynamic, static, and switching threshold near the marks) ensure greater flexibility during commissioning. The integrated IO-Link interface can be used to access the parameter settings. This speeds up and simplifies format changes. The KTM reliably detects marks even in conditions with weak contrast ratios and is therefore ideal for use in a wide range of applications, in the stainless-steel version, it can even be used in harsh environments during intensive cleaning.

- 0

- 1